Page 83 - CITS - Fitter Trade Practical - Volume -2

P. 83

FITTER - CITS

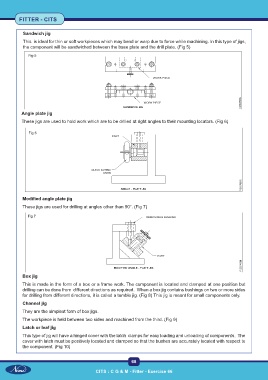

Sandwich jig

This is ideal for thin or soft workpieces which may bend or warp due to force while machining. In this type of jigs,

the component will be sandwiched between the base plate and the drill plate. (Fig 5)

Fig 5

Angle plate jig

These jigs are used to hold work which are to be drilled at right angles to their mounting locators. (Fig 6)

Fig 6

Modified angle plate jig

These jigs are used for drilling at angles other than 90°. (Fig 7)

Fig 7

Box jig

This is made in the form of a box or a frame work. The component is located and clamped at one position but

drilling can be done from different directions as required. When a box jig contains bushings on two or more sides

for drilling from different directions, it is called a tumble jig. (Fig 8) This jig is meant for small components only.

Channel jig

They are the simplest form of box jigs.

The workpiece is held between two sides and machined from the third. (Fig 9)

Latch or leaf jig

This type of jig will have a hinged cover with the latch clamps for easy loading and unloading of components. The

cover with latch must be positively located and clamped so that the bushes are accurately located with respect to

the component. (Fig 10)

68

CITS : C G & M - Fitter - Exercise 66