Page 161 - CITS - Fitter - Trade Theory

P. 161

FITTER - CITS

LESSON 27 : Introduction, classification, Type and uses

of Bearings

Objectives

At the end of this lesson you shall be able to

• introduction to bearing

• state the parts of bearing

• state the types of bearing and uses

Introduction

Bearings are designed to facilitate smooth and efficient motion by minimizing friction and wear between two sur-

faces in relative motion. They support radial, axial, or combined loads and enable rotational or linear movement

in machines and mechanical systems. Bearings typically consist of an inner and outer ring, rolling elements (such

as balls or rollers), a cage or separator to keep the rolling elements spaced apart, and sometimes seals or shields

to protect against contamination.

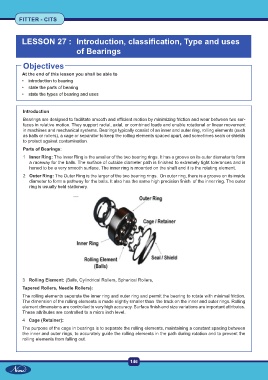

Parts of Bearings:

1 Inner Ring: The Inner Ring is the smaller of the two bearing rings. It has a groove on its outer diameter to form

a raceway for the balls. The surface of outside diameter path is finished to extremely tight tolerances and is

honed to be a very smooth surface. The inner ring is mounted on the shaft and it is the rotating element.

2 Outer Ring: The Outer Ring is the larger of the two bearing rings. On outer ring, there is a groove on its inside

diameter to form a pathway for the balls. It also has the same high precision finish of the inner ring. The outer

ring is usually held stationery.

3 Rolling Element: (Balls, Cylindrical Rollers, Spherical Rollers,

Tapered Rollers, Needle Rollers):

The rolling elements separate the inner ring and outer ring and permit the bearing to rotate with minimal friction.

The dimension of the rolling elements is made slightly smaller than the track on the inner and outer rings. Rolling

element dimensions are controlled to very high accuracy. Surface finish and size variations are important attributes.

These attributes are controlled to a micro inch level.

4 Cage (Retainer):

The purpose of the cage in bearings is to separate the rolling elements, maintaining a constant spacing between

the inner and outer rings, to accurately guide the rolling elements in the path during rotation and to prevent the

rolling elements from falling out.

146

CITS : CG & M - Fitter - Lesson 27