Page 245 - CTS - Mechanic Diesel - TP

P. 245

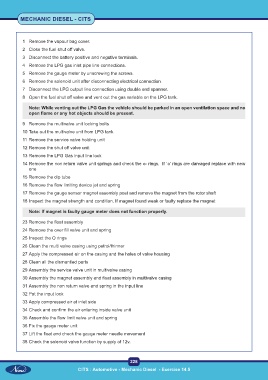

MECHANIC DIESEL - CITS

1 Remove the vapour bag cover.

2 Close the fuel shut off valve.

3 Disconnect the battery positive and negative terminals.

4 Remove the LPG gas inlet pipe line connections.

5 Remove the gauge meter by unscrewing the screws.

6 Remove the solenoid unit after disconnecting electrical connection.

7 Disconnect the LPG output line connection using double end spanner.

8 Open the fuel shut off valve and vent out the gas variable on the LPG tank.

Note: While venting out the LPG Gas the vehicle should be parked in an open ventilation space and no

open flame or any hot objects should be present.

9 Remove the multivalve unit locking bolts

10 Take out the multivalve unit from LPG tank

11 Remove the service valve holding unit

12 Remove the shut off valve unit

13 Remove the LPG Gas input line lock

14 Remove the non return valve unit springs and check the o- rings. If `o’ rings are damaged replace with new

one

15 Remove the dip tube

16 Remove the flow limiting device jet and spring

17 Remove the gauge sensor magnet assembly post and remove the magnet from the rotor shaft

18 Inspect the magnet strength and condition. If magnet found weak or faulty replace the magnet

Note: If magnet is faulty gauge meter does not function properly.

23 Remove the float assembly

24 Remove the over fill valve unit and spring

25 Inspect the O rings

26 Clean the multi valve casing using petrol/thinner

27 Apply the compressed air on the casing and the holes of valve housing

28 Clean all the dismantled parts

29 Assembly the service valve unit in multivalve casing

30 Assembly the magnet assembly and float assembly in multivalve casing

31 Assembly the non return valve and spring in the input line

32 Put the input lock

33 Apply compressed air at inlet side

34 Check and confirm the air entering inside valve unit

35 Assemble the flow limit valve unit and spring

36 Fix the gauge meter unit

37 Lift the float and check the gauge meter needle movement

38 Check the solenoid valve function by supply of 12v.

228

CITS : Automotive - Mechanic Diesel - Exercise 14.5