Page 28 - CTS - Mechanic Diesel - TP

P. 28

MECHANIC DIESEL - CITS

Check visually, the grease nipple holder for any damage.

Fill up the gun with the specified grease.

Close the grease gun and operate the lever till the grease comes out continuously from the nipple with pressure.

Use the gun for the required purpose.

Oil spray gun

Check visually the oil spray gun nozzle, nozzle holder, operating lever, air hose for any damage.

Fill the spray gun with SAE20W/40 and kerosene mixture in the ratio of 1:20.

Connect the oil spray gun to the quick release coupler.

Operate the oil spray gun.

See that the oil is sprayed at pressure and spray over panel joints and moving part only.

Close the air-hose connections and takeout the oil spray gun.

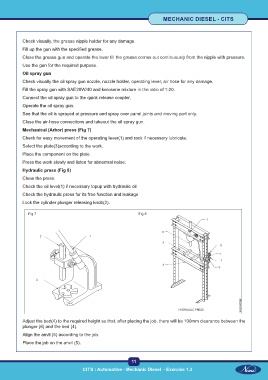

Mechanical (Arbor) press (Fig 7)

Check for easy movement of the operating lever(1) and rack if necessary lubricate.

Select the plate(3)according to the work.

Place the component on the plate.

Press the work slowly and listen for abnormal noise.

Hydraulic press (Fig 8)

Clean the press.

Check the oil level(1) if necessary topup with hydraulic oil

Check the hydraulic press for its free function and leakage

Lock the cylinder plunger releasing knob(2).

Fig 7 Fig 8

Adjust the bed(4) to the required height so that, after placing the job, there will be 100mm clearance between the

plunger (6) and the bed (4).

Align the anvil (5) according to the job.

Place the job on the anvil (5).

11

CITS : Automotive - Mechanic Diesel - Exercise 1.3