Page 59 - CTS - Mechanic Diesel - TP

P. 59

MECHANIC DIESEL - CITS

EXERCISE 2.18: Practice on removing and measuring the

piston

Objectives

At the end of this exercise you shall be able to

• remove the piston rings and piston pin from the piston

• remove the piston from the connecting rod

• check the piston ring clearance

• check the wear of piston skirt and crown.

Requirements

Tools/Instruments Materials/Components

• Trainee’s tool kit - 1 No. • Cotton waste - as reqd.

• Feeler gauge - 1 No. • Kerosene - as reqd.

• Outside micrometer - 1 No. • Piston rings - as reqd.

Procedure

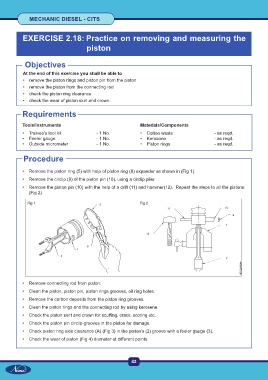

• Remove the piston ring (5) with help of piston ring (8) expander as shown in (Fig 1).

• Remove the circlip (9) of the piston pin (10), using a circlip plier.

• Remove the piston pin (10) with the help of a drift (11) and hammer(12). Repeat the steps to all the pistons.

(Fig 2)

Fig 1 Fig 2

• Remove connecting rod from piston.

• Clean the piston, piston pin, piston rings grooves, oil ring holes.

• Remove the carbon deposits from the piston ring grooves.

• Clean the piston rings and the connecting rod by using kerosene.

• Check the piston skirt and crown for scuffing, crack, scoring etc.

• Check the piston pin circlip grooves in the piston for damage.

• Check piston ring side clearance (A) (Fig 3) in the piston’s (2) groove with a feeler gauge (3).

• Check the wear of piston (Fig 4) diameter at different points.

42