Page 150 - Mechanic Diesel - TT

P. 150

MECHANIC DIESEL - CITS

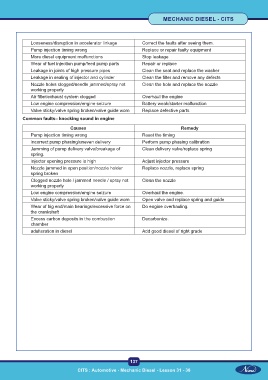

Looseness/disruption in accelerator linkage Correct the faults after seeing them.

Pump injection timing wrong Replace or repair faulty equipment

More diesel equipment malfunctions Stop leakage

Wear of fuel injection pump/feed pump parts Repair or replace

Leakage in joints of high pressure pipes Clean the seat and replace the washer

Leakage in sealing of injector and cylinder Clean the filter and remove any defects

Nozzle holes clogged/needle jammed/spray not Clean the hole and replace the nozzle

working properly

Air filter/exhaust system clogged Overhaul the engine

Low engine compression/engine seizure Battery weak/starter malfunction

Valve sticky/valve spring broken/valve guide worn Replace defective parts.

Common faults– knocking sound in engine

Causes Remedy

Pump injection timing wrong Reset the timing

Incorrect pump phasing/uneven delivery Perform pump phasing calibration

Jamming of pump delivery valve/breakage of Clean delivery valve/replace spring

spring.

Injector opening pressure is high Adjust injector pressure

Nozzle jammed in open position/nozzle holder Replace nozzle, replace spring

spring broken

Clogged nozzle hole / jammed needle / spray not Clean the nozzle

working properly

Low engine compression/engine seizure Overhaul the engine.

Valve sticky/valve spring broken/valve guide worn Open valve and replace spring and guide

Wear of big end/main bearings/excessive force on Do engine overhauling.

the crankshaft

Excess carbon deposits in the combustion Decarbonize.

chamber

adulteration in diesel Add good diesel of right grade

137

CITS : Automotive - Mechanic Diesel - Lesson 31 - 38 CITS : Automotive - Mechanic Diesel - Lesson 31 - 38