Page 217 - Mechanic Diesel - TT

P. 217

MECHANIC DIESEL - CITS

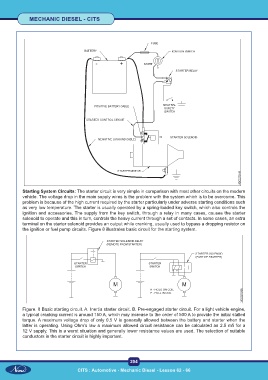

Starting System Circuits: The starter circuit is very simple in comparison with most other circuits on the modern

vehicle. The voltage drop in the main supply wires is the problem with the system which is to be overcome. This

problem is because of the high current required by the starter particularly under adverse starting conditions such

as very low temperature. The starter is usually operated by a spring-loaded key switch, which also controls the

ignition and accessories. The supply from the key switch, through a relay in many cases, causes the starter

solenoid to operate and this in turn, controls the heavy current through a set of contacts. In some cases, an extra

terminal on the starter solenoid provides an output while cranking, usually used to bypass a dropping resistor on

the ignition or fuel pump circuits. Figure 8 illustrates basic circuit for the starting system.

Figure. 8 Basic starting circuit. A. Inertia starter circuit. B. Pre-engaged starter circuit. For a light vehicle engine,

a typical cranking current is around 150 A, which may increase to the order of 500 A to provide the initial stalled

torque. A maximum voltage drop of only 0.5 V is generally allowed between the battery and starter when the

latter is operating. Using Ohm’s law a maximum allowed circuit resistance can be calculated as 2.5 mfi for a

12 V supply. This is a worst situation and generally lower resistance values are used. The selection of suitable

conductors in the starter circuit is highly important.

204

CITS : Automotive - Mechanic Diesel - Lesson 62 - 66