Page 218 - Mechanic Diesel - TT

P. 218

MECHANIC DIESEL - CITS

The basic starting system includes the following components:

1 Battery.

2 Cable and wires.

3 Ignition switch.

4 Starter solenoid or relay.

5 Starter motor.

6 Starter drive and flywheel ring gear.

7 Starting safety switch.

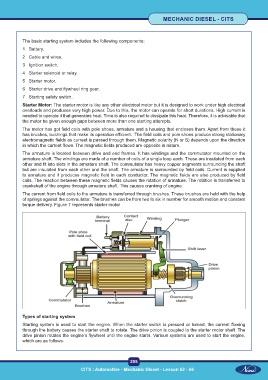

Starter Motor: The starter motor is like any other electrical motor but it is designed to work under high electrical

overloads and produces very high power. Due to this, the motor can operate for short durations. High current is

needed to operate it that generates heat. Time is also required to dissipate this heat. Therefore, it is advisable that

the motor be given enough gaps between more than one starting attempts.

The motor has got field coils with pole shoes, armature and a housing that encloses them. Apart from these it

has brushes, bushings that make its operation efficient. The field coils and pole shoes produce strong stationary

electromagnetic fields as current is passed through them. Magnetic polarity (N or S) depends upon the direction

in which the current flows. The magnetic fields produced are opposite in nature.

The armature is located between drive and end frames. It has windings and the commutator mounted on the

armature shaft. The windings are made of a number of coils of a single loop each. These are insulated from each

other and fit into slots in the armature shaft. The commutator has heavy copper segments surrounding the shaft

but are insulated from each other and the shaft. The armature is surrounded by field coils. Current is supplied

to armature and it produces magnetic field in each conductor. The magnetic fields are also produced by field

coils. The reaction between these magnetic fields causes the rotation of armature. The rotation is transferred to

crankshaft of the engine through armature shaft. This causes cranking of engine.

The current from field coils to the armature is transferred through brushes. These brushes are held with the help

of springs against the commutator. The brushes can be from two to six in number for smooth motion and constant

torque delivery. Figure 7 represents starter motor

Types of starting system

Starting system is used to start the engine. When the starter switch is pressed or turned, the current flowing

through the battery causes the starter shaft to rotate. The drive pinion is coupled to the starter motor shaft. The

drive pinion rotates the engine’s flywheel until the engine starts. Various systems are used to start the engine,

which are as follows-

205

CITS : Automotive - Mechanic Diesel - Lesson 62 - 66