Page 327 - Mechanic Diesel - TT

P. 327

MECHANIC DIESEL - CITS

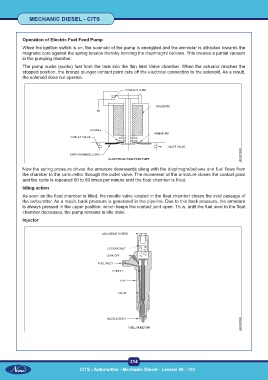

Operation of Electric Fuel Feed Pump

When the ignition switch is on, the solenoid of the pump is energized and the ammeter is attracted towards the

magnetic core against the spring tension thereby bending the diaphragm/ bellows. This creates a partial vacuum

in the pumping chamber.

The pump sucks (sucks) fuel from the tank into the thin Inlet Valve chamber. When the actuator reaches the

stopped position, the bronze plunger contact point cuts off the electrical connection to the solenoid. As a result,

the solenoid does not operate.

Now the spring pressure drives the armature downwards along with the diaphragm/bellows and fuel flows from

the chamber to the carburettor through the outlet valve. The movement of the armature closes the contact point

and the cycle is repeated 50 to 60 times per minute until the float chamber is filled.

Idling action

As soon as the float chamber is filled, the needle valve located in the float chamber closes the inlet passage of

the carburettor. As a result, back pressure is generated in the pipeline. Due to this back pressure, the armature

is always pressed in the upper position, which keeps the contact joint open. Thus, until the fuel level in the float

chamber decreases, the pump remains in idle state.

Injector

314

CITS : Automotive - Mechanic Diesel - Lesson 98 - 103