Page 64 - Mechanic Diesel - TT

P. 64

MECHANIC DIESEL - CITS

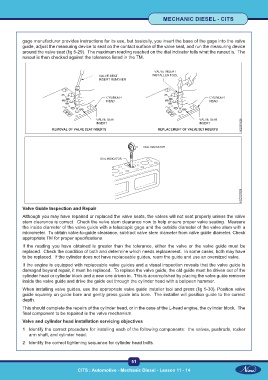

gage manufacturer provides instructions for its use, but basically, you insert the base of the gage into the valve

guide, adjust the measuring device to seat on the contact surface of the valve seat, and run the measuring device

around the valve seat (fig 5-29). The maximum reading reached on the dial indicator tells what the runout is. The

runout is then checked against the tolerance listed in the TM.

Valve Guide Inspection and Repair

Although you may have repaired or replaced the valve seats, the valves will not seat properly unless the valve

stem clearance is correct. Check the valve stem clearance now to help ensure proper valve seating. Measure

the inside diameter of the valve guide with a telescopic gage and the outside diameter of the valve stem with a

micrometer. To obtain valve-to-guide clearance, subtract valve stem diameter from valve guide diameter. Check

appropriate TM for proper specifications.

If the reading you have obtained is greater than the tolerance, either the valve or the valve guide must be

replaced. Check the condition of both and determine which needs replacement. In some cases, both may have

to be replaced. If the cylinder does not have replaceable guides, ream the guide and use an oversized valve.

If the engine is equipped with replaceable valve guides and a visual inspection reveals that the valve guide is

damaged beyond repair, it must be replaced. To replace the valve guide, the old guide must be driven out of the

cylinder head or cylinder block and a new one driven in. This is accomplished by placing the valve guide remover

inside the valve guide and drive the guide out through the cylinder head with a ballpeen hammer.

When installing valve guides, use the appropriate valve guide installer tool and press (fig 5-30). Position valve

guide squarely on guide bore and gently press guide into bore. The installer will position guide to the correct

depth.

This should complete the repairs of the cylinder head, or in the case of the L-head engine, the cylinder block. The

final component to be repaired is the valve mechanism

Valve and cylinder head installation servicing objectives

1 Identify the correct procedure for installing each of the following components: the valves, pushrods, rocker

arm shaft, and cylinder head.

2 Identify the correct tightening sequence for cylinder head bolts.

51

CITS : Automotive - Mechanic Diesel - Lesson 11 - 14 CITS : Automotive - Mechanic Diesel - Lesson 11 - 14