Page 97 - Mechanic Diesel - TT

P. 97

MECHANIC DIESEL - CITS

into the throttle body, through the bypass passage into the engine. As the bypass screw is opened and closed,

which it can control the airflow through the bypass circuit. So the throttle body main function is the changed the

flow velocity and pressure during transient operation of the engine, which the throttle position is changed by per

driver’s demand. So the schematic of a throttle body describing air flow path is shown in Figure 1, Air flow enters

into the throttle and move downstream, Throttle body restricts the amount of air flow into the engine based on

throttle position.

[1] have carried out simulation of time- dependent flow through throttle valve to determine flow mechanisms

various throttle plate angles and compared the results with hexahedral and tetrahedral meshes. Chen and Chen

[2] analyzed small airflow rate at engine idling by using CFD analysis to aid throttle body design and to study

tolerance effect on the estimated airflow rate.

The limited studies are reported on numerical simulation of flow through the throttle body, it is proposed to analyze

the flow through the throttle body assembly at different throttle valve opening and closing use CFD.

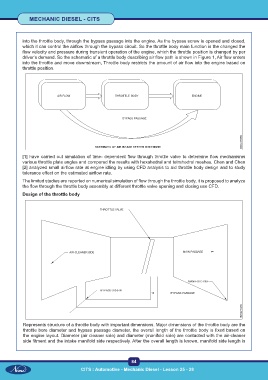

Design of the throttle body

Represents structure of a throttle body with important dimensions. Major dimensions of the throttle body are the

throttle bore diameter and bypass passage diameter, the overall length of the throttle body is fixed based on

the engine layout. Diameter (air cleaner side) and diameter (manifold side) are contacted with the air-cleaner

side fitment and the intake manifold side respectively. After the overall length is known, manifold side length is

84

CITS : Automotive - Mechanic Diesel - Lesson 25 - 28