Page 102 - Mechanic Diesel - TT

P. 102

MECHANIC DIESEL - CITS

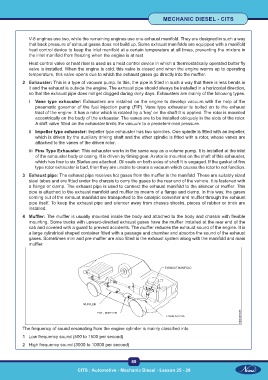

V-8 engines use two, while the remaining engines use one exhaust manifold. They are designed in such a way

that back pressure of exhaust gases does not build up. Some exhaust manifolds are equipped with a manifold

heat control device to keep the inlet manifold at a certain temperature at all times, preventing the mixture in

the inlet manifold from freezing when the engine is at rest.

Heat control valve or heat riser is used as a heat control device in which a thermostatically operated butter fly

valve is installed. When the engine is cold, this valve is closed and when the engine warms up to operating

temperature, this valve opens due to which the exhaust gases go directly into the muffler.

2 Exhauster: This is a type of vacuum pump. In this, the pipe is fitted in such a way that there is less bends in

it and the exhaust is outside the engine. The exhaust pipe should always be installed in a horizontal direction,

so that the exhaust pipe does not get clogged during rainy days. Exhausters are mainly of the following types.

i Vane type exhauster: Exhausters are installed on the engine to develop vacuum with the help of the

pneumatic governor of the fuel injection pump (FIP). Vane type exhauster is bolted on to the exhaust

tract of the engine. It has a rotor which is rotated by a ‘key’ on the shaft It is applied. The rotor is mounted

eccentrically on the body of the exhauster. The vanes are to be installed obliquely in the slots of the rotor.

A shift valve fitted on the exhauster limits the vacuum to a predetermined pressure.

ii Impeller type exhauster: Impeller type exhauster has two spindles. One spindle is fitted with an impeller,

which is driven by the auxiliary driving shaft and the other spindle is fitted with a rotor, whose vanes are

attached to the vanes of the driven rotor.

iii Fins Type Exhauster: This exhauster works in the same way as a volume pump. It is installed at the inlet

of the exhauster body or casing. It is driven by timing gear. A rotor is mounted on the shaft of this exhauster,

which has four to six Blades are attached. Oil seals on both sides of shaft It is engaged. If the gasket of fins

type rotor exhauster is bad, then they are unable to create a vacuum which causes the rotor to not function.

3 Exhaust pipe: The exhaust pipe receives hot gases from the muffler in the manifold. These are suitably sized

steel tubes and are fitted under the chassis to carry the gases to the rear end of the vehicle. It is fastened with

a flange or clamp. The exhaust pipe is used to connect the exhaust manifold to the silencer or muffler. This

pipe is attached to the exhaust manifold and muffler by means of a flange and clamp. In this way, the gases

coming out of the exhaust manifold are transported to the catalytic converter and muffler through the exhaust

pipe itself. To keep the exhaust pipe and silencer away from chassis shocks, pieces of rubber or brick are

installed.

4 Muffler: The muffler is usually mounted inside the body and attached to the body and chassis with flexible

mounting. Some trucks with upward-directed exhaust gases have the muffler installed at the rear end of the

cab and covered with a guard to prevent accidents. The muffler reduces the exhaust sound of the engine. It is

a large cylindrical shaped container fitted with a passage and chamber and absorbs the sound of the exhaust

gases. Sometimes mini and pre-muffler are also fitted in the exhaust system along with the manifold and main

muffler.

The frequency of sound emanating from the engine cylinder is mainly classified into

1 Low frequency sound (500 to 1500 per second)

2 High frequency sound (3000 to 10000 per second)

89

CITS : Automotive - Mechanic Diesel - Lesson 25 - 28 CITS : Automotive - Mechanic Diesel - Lesson 25 - 28