Page 172 - CTS - Sewing Technology - TP - Volume - 2-0

P. 172

SEWING TECHNOLOGY - CITS

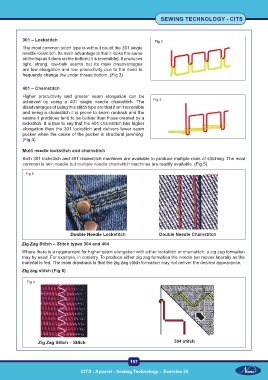

301 – Lockstitch Fig 3

The most common stitch type is without doubt the 301 single

needle lockstitch. Its main advantage is that it looks the same

on the top as it does on the bottom [it is reversible]. It produces

tight, strong, low-bulk seams but its main disadvantages

are low elongation and low productivity due to the need to

frequently change the under thread bobbin. (Fig 3)

401 – Chainstitch

Higher productivity and greater seam elongation can be

achieved by using a 401 single needle chainstitch. The Fig 4

disadvantages of using this stitch type are that it isn’t reversible

and being a chainstitch it is prone to seam runback and the

seams it produces tend to be bulkier than those created by a

lockstitch. It is true to say that the 401 chainstitch has higher

elongation than the 301 lockstitch and delivers lower seam

pucker when the cause of the pucker is structural jamming.

(Fig 4)

Multi needle lockstitch and chainstitch

Both 301 lockstitch and 401 chainstitch machines are available to produce multiple rows of stitching. The most

common is twin needle but multiple needle chainstitch machines are readily available. (Fig 5)

Fig 5

Double Needle Lockstitch Double Needle Chainstitch

Zig Zag Stitch – Stitch types 304 and 404

Where there is a requirement for higher seam elongation with either lockstitch or chainstitch, a zig zag formation

may by used. For example, in corsetry. To produce either zig zag formation the needle bar moves laterally as the

material is fed. The main drawback is that the zig zag stitch formation may not deliver the desired appearance.

Zig zag stitch (Fig 6)

Fig 6

Zig Zag Stitch – Stitch 304 stitch

157

CITS : Apparel - Sewing Technology - Exercise 34