Page 235 - CITS - Welder - Trade Practical

P. 235

WELDER - CITS

- Thoroughly clean the pieces to be joined. Pay particular attention to the top of the plate, the sidewalls of the

groove and the underside of the joint. Grind or file a1.5 mm root face on each beveled edge

- Tack the pieces together and position

- Put spacers under the plate so that you don’t weld the plate to your table

- Hold the gun perpendicular to the joint and strike the arc at the tack. Move the torch from left to right end of

the joint i.e use back hand technique. Weave the gun from side to side. When the gun is in the center of the

joint, watch the arc very closely. By concentrating the arc on the leadingedge of the puddle, you can cause the

bead to penetrate through the joint and fuse both rootfaces.If you bring the arc too far down in the puddle, the

wire will go through the joint and the arc will become very erratic.If you allow the arc to go to of ar upon the

puddle,your penetration will decrease and you will not penetrate the joint.Practice will help you use the arc to

control the flow of the weld puddle

- Complete the joint using the bead sequence. Use a slight weave to help the weld flow and to fuse to the side

walls of the groove and the previous beads

- When you have completed the weld, cool it and examine it. The root should show full penetration along the

entirelength. The rootreinforcement should protrude beyond the joint from 0.5 to 1mm. The face of the weld

should merge smoothly with the base metal. There inforcement should be atleast 1mm above the surface of

the base metal and also should not exceed beyond 1.5.

Note: Wear protective clothing.

• Tack-weld on both ends.

• Set the ‘V’ joint in a flat position.

• Deposit root run by using with 100-110 amps current. By outer head position.

Note: Ensure an electrode angle of 45° with the fillet corner and 80° with the welding line.

• Remove the slag with a chipping hammer and clean with a wire brush.

• Use tongs to hold the job.

• Wear chipping goggle for the protection of eyes.

• Deposit the final covering run with a weave motion with150-160amps welding current.

Note: Prevent the upper edge of the plate from melting off.

• Remove the slag from the final weld and clean thoroughly.

Note: Use a weld gauge to check the fillet size.

• Inspect the lap fillet weld for surface defects and size.

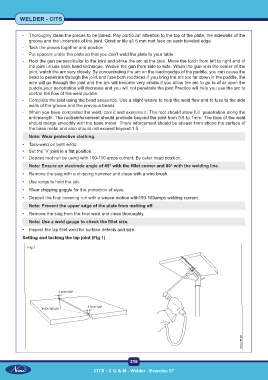

Setting and tacking the lap joint (Fig 1)

Fig 1

218

CITS : C G & M - Welder - Exercise 57 CITS : C G & M - Welder - Exercise 57