Page 236 - CITS - Welder - Trade Practical

P. 236

WELDER - CITS

Skill Sequence

Reviewsingle V butt joint on M.S. plate (10 mm. thick plate) in over

head position by GMAW

Objectives: At the end of this exercise you shall be able to

• review single v butt joint on m.s. plate (10 mm. thick plate) in over head position by GMAW.

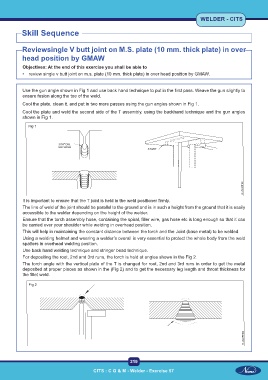

Use the gun angle shown in Fig 1 and use back hand technique to put in the first pass. Weave the gun slightly to

ensure fusion along the toe of the weld.

Cool the plate, clean it, and put in two more passes using the gun angles shown in Fig 1.

Cool the plate and weld the second side of the T assembly, using the backhand technique and the gun angles

shown in Fig 1.

Fig 1

It is important to ensure that the T joint is held in the weld positioner firmly.

The line of weld of the joint should be parallel to the ground and is in such a height from the ground that it is easily

accessible to the welder depending on the height of the welder.

Ensure that the torch assembly hose, containing the spiral, filler wire, gas hose etc is long enough so that it can

be carried over your shoulder while welding in overhead position.

This will help in maintaining the constant distance between the torch and the Joint (base metal) to be welded.

Using a welding helmet and wearing a welder’s overall is very essential to protect the whole body from the weld

spatters in overhead welding position.

Use back hand welding technique and stringer bead technique.

For depositing the root, 2nd and 3rd runs, the torch is held at angles shown in the Fig 2.

The torch angle with the vertical plate of the T is changed for root, 2nd and 3rd runs in order to get the metal

deposited at proper places as shown in the (Fig 2) and to get the necessary leg length and throat thickness for

the fillet weld.

Fig 2

219

CITS : C G & M - Welder - Exercise 57