Page 243 - CITS - Welder - Trade Practical

P. 243

WELDER - CITS

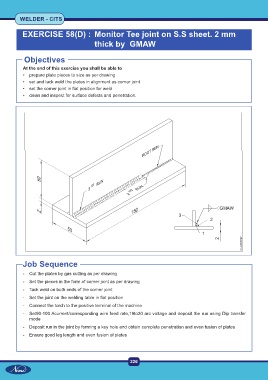

EXERCISE 58(D) : Monitor Tee joint on S.S sheet. 2 mm

thick by GMAW

Objectives

At the end of this exercise you shall be able to

• prepare plate pieces to size as per drawing

• set and tack weld the plates in alignment as corner joint

• set the corner joint in flat position for weld

• clean and inspect for surface defects and penetration.

Job Sequence

- Cut the plates by gas cutting as per drawing

- Set the pieces in the form of corner joint as per drawing

- Tack weld on both ends of the corner joint

- Set the joint on the welding table in flat position

- Connect the torch to the positive terminal of the machine

- Set90-100 Acurrent/corresponding wire feed rate,19to20 arc voltage and deposit the run using Dip transfer

mode

- Deposit run in the joint by forming a key hole and obtain complete penetration and even fusion of plates

- Ensure good leg length and even fusion of plates

226