Page 267 - CITS - Welder - Trade Practical

P. 267

WELDER - CITS

• Clean the weld area thoroughly.

• Inspect the job for free defects.

• Visual inspection : slight convexity, uniform width, uniform ripples And free from under cut at the toes of

the weld indicate a smooth

Skill Sequence

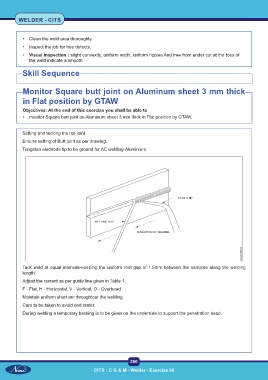

Monitor Square butt joint on Aluminum sheet 3 mm thick

in Flat position by GTAW

Objectives: At the end of this exercise you shall be able to

• monitor Square butt joint on Aluminum sheet 3 mm thick in Flat position by GTAW.

Setting and tacking the lap joint

Ensure setting of Butt joint as per drawing.

Tungsten electrode tip to be ground for AC welding-Aluminium.

Tack weld at equal intervals-keeping the uniform root gap of 1.5mm between the samples along the welding

length.

Adjust the current as per guide line given in Table 1.

F - Flat, H - Horizontal, V - Vertical, O - Overhead

Maintain uniform short arc throughtout the welding.

Care to be taken to avoid end crater.

During welding a temporary backing is to be given on the underside to support the penetration bead.

250

CITS : C G & M - Welder - Exercise 66