Page 308 - CITS - Welder - Trade Practical

P. 308

WELDER - CITS

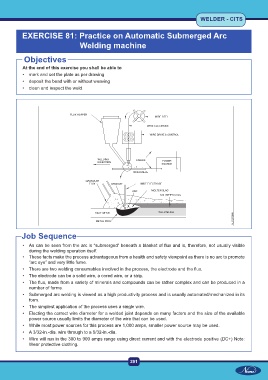

EXERCISE 81: Practice on Automatic Submerged Arc

Welding machine

Objectives

At the end of this exercise you shall be able to

• mark and set the plate as per drawing

• deposit the bead with or without weaving

• clean and inspect the weld.

Job Sequence

• As can be seen from the arc is “submerged” beneath a blanket of flux and is, therefore, not usually visible

during the welding operation itself.

• These facts make the process advantageous from a health and safety viewpoint as there is no arc to promote

“arc eye” and very little fume.

• There are two welding consumables involved in the process, the electrode and the flux.

• The electrode can be a solid wire, a cored wire, or a strip.

• The flux, made from a variety of minerals and compounds can be rather complex and can be produced in a

number of forms.

• Submerged arc welding is viewed as a high productivity process and is usually automated/mechanized in its

form.

• The simplest application of the process uses a single wire.

• Electing the correct wire diameter for a welded joint depends on many factors and the size of the available

power source usually limits the diameter of the wire that can be used.

• While most power sources for this process are 1,000 amps, smaller power source may be used.

• A 3/32-in.-dia. wire through to a 5/32-in.-dia.

• Wire will run in the 300 to 900 amps range using direct current and with the electrode positive (DC+) Note:

Wear protective clothing.

291

CITS : CG & M - Welder - Exercise 80