Page 304 - CITS - Welder - Trade Practical

P. 304

WELDER - CITS

• Deposit run in the joint by forming a key hole and obtain complete penetration and even fusion of plates.

• Ensure good leg length and even fusion of plates.

• Select dia 1.mm m.s electrode

• Set 90 to 100 amps current

• Ensure proper root penetration and even fusion.

• Wide and weaving motion the side of corner joints.

Note: Wear protective clothing.

Skill Sequence

Make Lap joint on Stainless steel sheet by Resistance Spot

welding MS sheets joining by Resistance Spot welding

Objectives: At the end of this exercise you shall be able to

• make lap joint on stainless steel sheet by resistance spot welding ms sheets joining by resistance spot

welding.

1 Set the pieces in the form of lap joint.

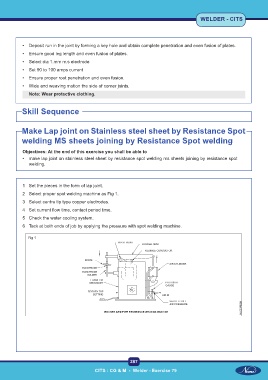

2 Select proper spot welding machine as Fig 1.

3 Select centre tip type copper electrodes.

4 Set current flow time, contact period time.

5 Check the water cooling system.

6 Tack at both ends of job by applying the pressure with spot welding machine.

Fig 1

287

CITS : CG & M - Welder - Exercise 79