Page 300 - CITS - Welder - Trade Practical

P. 300

WELDER - CITS

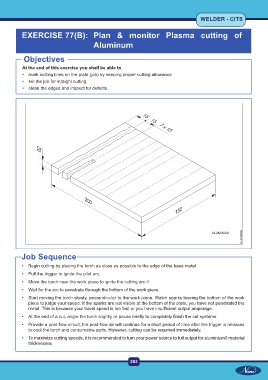

EXERCISE 77(B): Plan & monitor Plasma cutting of

Aluminum

Objectives

At the end of this exercise you shall be able to

• mark cutting lines on the plate (job) by keeping proper cutting allowance

• set the job for straight cutting

• clean the edges and inspect for defects.

Job Sequence

• Begin cutting by placing the torch as close as possible to the edge of the base metal.

• Pull the trigger to ignite the pilot arc.

• Move the torch near the work piece to ignite the cutting arc 4

• Wait for the arc to penetrate through the bottom of the work piece.

• Start moving the torch slowly, perpendicular to the work piece. Watch sparks leaving the bottom of the work

piece to judge your speed. If the sparks are not visible at the bottom of the plate, you have not penetrated the

metal. This is because your travel speed is too fast or you have insufficient output amperage.

• At the end of a cut, angle the torch slightly or pause briefly to completely finish the cut systems.

• Provide a post-flow circuit, the post-flow air will continue for a short period of time after the trigger is releases

to cool the torch and consumable parts. However, cutting can be resumed immediately.

• To maximize cutting speeds, it is recommended to turn your power source to full output for aluminium0 material

thicknesses.

283