Page 297 - CITS - Welder - Trade Practical

P. 297

WELDER - CITS

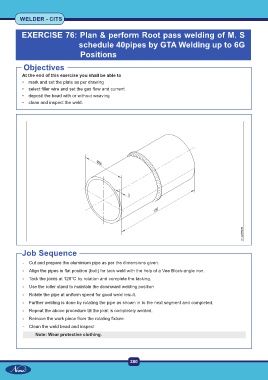

EXERCISE 76: Plan & perform Root pass welding of M. S

schedule 40pipes by GTA Welding up to 6G

Positions

Objectives

At the end of this exercise you shall be able to

• mark and set the plate as per drawing

• select filler wire and set the gas flow and current

• deposit the bead with or without weaving

• clean and inspect the weld.

Job Sequence

- Cut and prepare the aluminium pipe as per the dimensions given.

- Align the pipes in flat position (butt) for tack weld with the help of a Vee Block-angle iron.

- Tack the joints at 120°C by rotation and complete the tacking.

- Use the roller stand to maintain the downward welding position

- Rotate the pipe at uniform speed for good weld result.

- Further welding is done by rotating the pipe as shown in to the next segment and completed.

- Repeat the above procedure till the joint is completely welded.

- Remove the work piece from the rotating fixture.

- Clean the weld bead and inspect

Note: Wear protective clothing.

280