Page 107 - CITS - Welder - Trade Theory

P. 107

WELDER - CITS

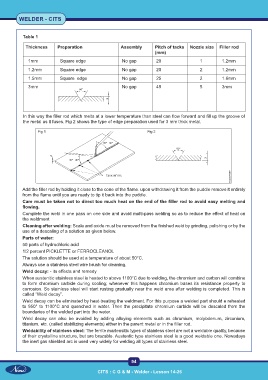

Table 1

Thickness Preparation Assembly Pitch of tacks Nozzle size Filler rod

(mm)

1mm Square edge No gap 20 1 1.2mm

1.2mm Square edge No gap 20 2 1.2mm

1.5mm Square edge No gap 25 2 1.6mm

3mm No gap 45 5 3mm

In this way the filler rod which melts at a lower temperature than steel can flow forward and fill up the groove of

the metal as it fuses. Fig 2 shows the type of edge preparation used for 3 mm thick metal.

Fig 1 Fig 2

Add the filler rod by holding it close to the cone of the flame. upon withdrawing it from the puddle remove it entirely

from the flame until you are ready to tip it back into the puddle.

Care must be taken not to direct too much heat on the end of the filler rod to avoid easy melting and

flowing.

Complete the weld in one pass on one side and avoid multi-pass welding so as to reduce the effect of heat on

the weldment.

Cleaning after welding: Scale and oxide must be removed from the finished weld by grinding, polishing or by the

use of a descaling of a solution as given below.

Parts of water:

50 parts of hydrochloric acid

1/2 percent PICKLETTE or FERROCLEANOL

The solution should be used at a temperature of about 50°C.

Always use a stainless steel wire brush for cleaning.

Weld decay: - its effects and remedy

When austenitic stainless steel is heated to above 1100°C due to welding, the chromium and carbon will combine

to form chromium carbide during cooling; whenever this happens chromium bases its resistance property to

corrosion. So stainless steel will start rusting gradually near the weld area after welding is completed. This is

called “Weld decay”.

Weld decay can be eliminated by heat-treating the weldment. For this purpose a welded part should e reheated

to 950° to 1100°C and quenched in water. Then the precipitate chromium carbide will be descaled from the

boundaries of the welded part into the water.

Weld decay can also be avoided by adding alloying elements such as chromium, molybdenum, zirconium,

titanium, etc. (called stabilizing elements) either in the parent metal or in the filler rod.

Weldability of stainless steel: The ferrite martensitic types of stainless steel are not a weldable quality, because

of their crystalline structure, but are brazable. Austentic type stainless steel is a good weldable one. Nowadays

the inert gas shielded arc is used very widely for welding all types of stainless steel.

94

CITS : C G & M - Welder - Lesson 14-26 CITS : C G & M - Welder - Lesson 14-26