Page 128 - CITS - Welder - Trade Theory

P. 128

WELDER - CITS

Fig 3

The technique of welding the second layer is the same as that for the first layer.

After completion of the second layer, play the flame again on the whole job for getting an even heat. This is called

‘post heating’.

Then allow the job to cool slowly by covering with a heap of lime or ash or dry sand.

Selection of filler rod

Filler rod should be selected according to the:

a) Kind or type of metal to be welded, i.e. ferrous, non-ferrous, hard facing (Table 1) thickness of metal to be

welded (including joint edge preparation)

b) Nature of joint to be made (i.e.), fusion welding or braze welding (non-fusion)

c) Welding technique to be used (leftward or rightward).

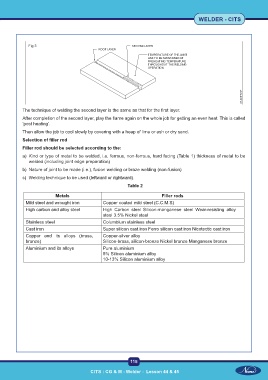

Table 2

Metals Filler rods

Mild steel and wrought iron Copper coated mild steel (C.C.M.S)

High carbon and alloy steel High Carbon steel Silicon-manganese steel Wear-resisting alloy

steel 3.5% Nickel steel

Stainless steel Columbium stainless steel

Cast iron Super silicon cast iron Ferro silicon cast iron Nicotectic cast iron

Copper and its alloys (brass, Copper-silver alloy

bronze) Silicon-brass, silicon-bronze Nickel bronze Manganese bronze

Aluminium and its alloys Pure aluminium

5% Silicon aluminium alloy

10-13% Silicon aluminium alloy

115

CITS : CG & M - Welder - Lesson 44 & 45 CITS : CG & M - Welder - Lesson 44 & 45