Page 137 - CITS - Welder - Trade Theory

P. 137

WELDER - CITS

Use electrodes specially manufactured for pipe welding to get good penetration, appearance and strength, (low

hydrogen electrodes, deep penetration electrodes etc.)

Downhill welding:

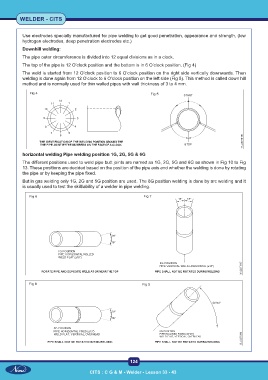

The pipe outer circumference is divided into 12 equal divisions as in a clock.

The top of the pipe is 12 O’clock position and the bottom is in 6 O’clock position. (Fig 4)

The weld is started from 12 O’clock position to 6 O’clock position on the right side vertically downwards. Then

welding is done again from 12 O’clock to 6 O’clock position on the left side (Fig 5). This method is called down hill

method and is normally used for thin walled pipes with wall thickness of 3 to 4 mm.

Fig 4 Fig 5

horizontal welding Pipe welding position 1G, 2G, 5G & 6G

The different positions used to weld pipe butt joints are named as 1G, 2G, 5G and 6G as shown in Fig 10 to Fig

13. These positions are decided based on the position of the pipe axis and whether the welding is done by rotating

the pipe or by keeping the pipe fixed.

But in gas welding only 1G, 2G and 5G position are used. The 6G position welding is done by arc welding and it

is usually used to test the skill/ability of a welder in pipe welding.

Fig 6 Fig 7

Fig 8 Fig 9

124

CITS : C G & M - Welder - Lesson 33 - 43