Page 247 - CITS - Welder - Trade Theory

P. 247

WELDER - CITS

f Proper procedure to be followed to control distortion.

g Proper selection of blow pipe nozzle and filler rod, flux and flame.

h Polarity of the electrodes in the case of DC welding current. Whether the cable connections are tight.

i Current setting according to the size of the electrode and position of welding.

h Whether any jigs and fixtures are necessary to ensure proper alignment.

Visual inspection during welding

The following points are to be checked. Studying the sequence of weld deposit.

a Examining whether each weld is cleaned adequately before making the next run in multi-run welding.

b Weld alignment proper need.

c Welding electrode should be dry need

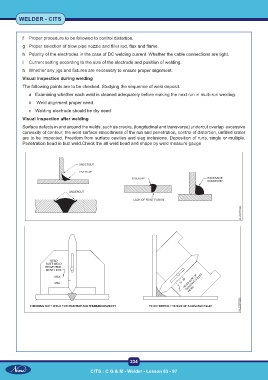

Visual inspection after welding

Surface defects in and around the welds, such as cracks, (longitudinal and transverse) undercut overlap excessive

convexity of contour, the weld surface smoothness of the run and penetration, control of distortion, unfilled crater

are to be inspected. Freedom from surface cavities and slag inclusions. Deposition of runs, single or multiple.

Penetration bead in butt weld.Check the all weld bead and shape by weld measure gauge

234

CITS : C G & M - Welder - Lesson 83 - 97