Page 244 - CITS - Welder - Trade Theory

P. 244

WELDER - CITS

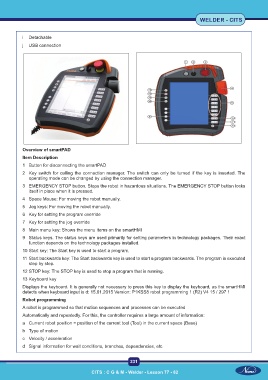

i Detachable

j USB connection

Overview of smartPAD

Item Description

1 Button for disconnecting the smartPAD

2 Key switch for calling the connection manager. The switch can only be turned if the key is inserted. The

operating mode can be changed by using the connection manager.

3 EMERGENCY STOP button. Stops the robot in hazardous situations. The EMERGENCY STOP button locks

itself in place when it is pressed.

4 Space Mouse: For moving the robot manually.

5 Jog keys: For moving the robot manually.

6 Key for setting the program override

7 Key for setting the jog override

8 Main menu key: Shows the menu items on the smartHMI

9 Status keys. The status keys are used primarily for setting parameters in technology packages. Their exact

function depends on the technology packages installed.

10 Start key: The Start key is used to start a program.

11 Start backwards key: The Start backwards key is used to start a program backwards. The program is executed

step by step.

12 STOP key: The STOP key is used to stop a program that is running.

13 Keyboard key

Displays the keyboard. It is generally not necessary to press this key to display the keyboard, as the smartHMI

detects when keyboard input is d: 15.01.2015 Version: P1KSS8 robot programming 1 (R2) V4 15 / 297 1

Robot programming

A robot is programmed so that motion sequences and processes can be executed

Automatically and repeatedly. For this, the controller requires a large amount of information:

a Current robot position = position of the current tool (Tool) in the current space (Base)

b Type of motion

c Velocity / acceleration

d Signal information for wait conditions, branches, dependencies, etc.

231

CITS : C G & M - Welder - Lesson 77 - 82