Page 240 - CITS - Welder - Trade Theory

P. 240

WELDER - CITS

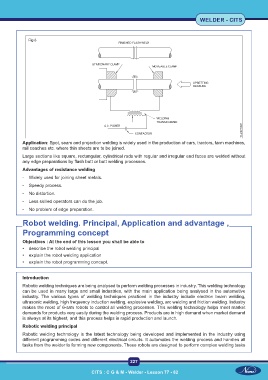

Fig 8

Application: Spot, seam and projection welding is widely used in the production of cars, tractors, farm machines,

rail coaches etc. where thin sheets are to be joined.

Large sections like square, rectangular, cylindrical rods with regular and irregular end faces are welded without

any edge preparations by flash butt or butt welding processes.

Advantages of resistance welding

- Widely used for joining sheet metals.

- Speedy process.

- No distortion.

- Less skilled operators can do the job.

- No problem of edge preparation.

Robot welding. Principal, Application and advantage ,

Programming concept

Objectives : At the end of this lesson you shall be able to

• describe the robot welding principal

• explain the robot welding application

• explain the robot programming concept.

Introduction

Robotic welding techniques are being analysed to perform welding processes in industry. This welding technology

can be used in many large and small industries, with the main application being analysed in the automotive

industry. The various types of welding techniques practiced in the industry include electron beam welding,

ultrasonic welding, high frequency induction welding, explosive welding, arc welding and friction welding. Industry

makes the most of 6-arm robots to control all welding processes. This welding technology helps meet market

demands for products very easily during the welding process. Products are in high demand when market demand

is always at its highest, and this process helps in rapid production and launch.

Robotic welding principal

Robotic welding technology is the latest technology being developed and implemented in the industry using

different programming codes and different electrical circuits. It automates the welding process and handles all

tasks from the welder to forming new components. These robots are designed to perform complex welding tasks

227

CITS : C G & M - Welder - Lesson 77 - 82