Page 238 - CITS - Welder - Trade Theory

P. 238

WELDER - CITS

Fig 3

Fig 4

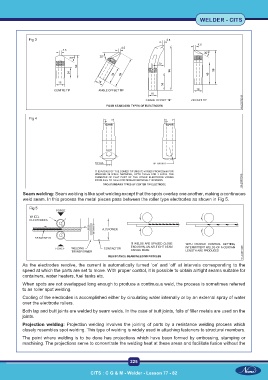

Seam welding: Seam welding is like spot welding except that the spots overlap one another, making a continuous

weld seam. In this process the metal pieces pass between the roller type electrodes as shown in Fig 5.

Fig 5

As the electrodes revolve, the current is automatically turned ‘on’ and ‘off’ at intervals corresponding to the

speed at which the parts are set to move. With proper control, it is possible to obtain airtight seams suitable for

containers, water heaters, fuel tanks etc.

When spots are not overlapped long enough to produce a continuous weld, the process is sometimes referred

to as roller spot welding.

Cooling of the electrodes is accomplished either by circulating water internally or by an external spray of water

over the electrode rollers.

Both lap and butt joints are welded by seam welds. In the case of butt joints, foils of filler metals are used on the

joints.

Projection welding: Projection welding involves the joining of parts by a resistance welding process which

closely resembles spot welding. This type of welding is widely used in attaching fasteners to structural members.

The point where welding is to be done has projections which have been formed by embossing, stamping or

machining. The projections serve to concentrate the welding heat at these areas and facilitate fusion without the

225

CITS : C G & M - Welder - Lesson 77 - 82 CITS : C G & M - Welder - Lesson 77 - 82