Page 233 - CITS - Welder - Trade Theory

P. 233

WELDER - CITS

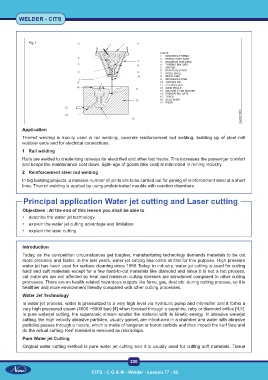

Fig 1

Application

Thermit welding is mainly used in rail welding, concrete reinforcement rod welding, building up of steel mill

wobbler ends and for electrical connections.

1 Rail welding

Rails are welded to create long railways for electrified and other fast tracks. This increases the passenger comfort

and keeps the maintenance cost down. Spill- age of goods (like coal) is minimized in mining industry.

2 Reinforcement steel rod welding

In big building projects, a massive number of joints are to be carried out for joining of reinforcement steel at a short

time. Thermit welding is applied by using prefabricated moulds with reaction chambers.

Principal application Water jet cutting and Laser cutting

Objectives : At the end of this lesson you shall be able to

• describe the water jet technology

• explain the water jet cutting advantage and limitation

• explain the laser cutting

Introduction

Today, as the competition circumstances get tougher, manufacturing technology demands materials to be cut

more precisely and faster. In the last years, water jet cutting has come at first for this purpose. High pressure

water jet has been used for surface cleaning since 1968 Today, in industry, water jet cutting is used for cutting

hard and soft materials except for a few hard-to-cut materials like diamond and since it is not a hot process,

cut materials are not affected by heat and minimum cutting stresses are introduced compared to other cutting

processes. There are no health-related hazardous outputs like fume, gas, dust etc. during cutting process, so it is

healthier and more environment friendly compared with other cutting processes.

Water Jet Technology

In water jet process, water is pressurized to a very high level via hydraulic pump and intensifier and it forms a

very high pressured steam (4000 ~6000 bar) [4] when focused through a sapphire, ruby or diamond orifice [4,5].

In pure waterjet cutting, the supersonic stream erodes the material with its kinetic energy. In abrasive waterjet

cutting, the high velocity abrasive particles, usually garnet, are introduced in a chamber and water with abrasive

particles passes through a nozzle, which is made of tungsten or boron carbide and then impact the kerf face and

do the actual cutting. Kerf material is removed as microchips.

Pure Water jet Cutting

Original water cutting method is pure water jet cutting and it is usually used for cutting soft materials. Tissue

220

CITS : C G & M - Welder - Lesson 77 - 82