Page 229 - CITS - Welder - Trade Theory

P. 229

WELDER - CITS

- Thicker steels can be welded in a single pass.

- High deposition rate.

- Residual stresses and distortion low.

- Less flux consumption.

- No spatter.

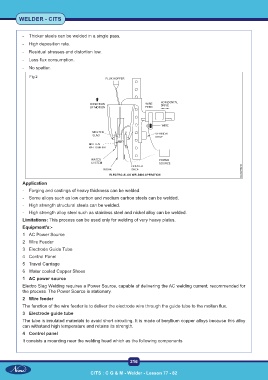

Fig 2

Application

- Forging and castings of heavy thickness can be welded.

- Some alloys such as low carbon and medium carbon steels can be welded.

- High strength structural steels can be welded.

- High strength alloy steel such as stainless steel and nickel alloy can be welded.

Limitations: This process can be used only for welding of very heavy plates.

Equipment’s:-

1 AC Power Source

2 Wire Feeder

3 Electrode Guide Tube

4 Control Panel

5 Travel Carriage

6 Water cooled Copper Shoes

1 AC power source

Electro Slag Welding requires a Power Source, capable of delivering the AC welding current, recommended for

the process. The Power Source is stationary.

2 Wire feeder

The function of the wire feeder is to deliver the electrode wire through the guide tube to the molten flux.

3 Electrode guide tube

The tube is insulated materials to avoid short circuiting. It is made of beryllium copper alloys because this alloy

can withstand high temperature and retains its strength.

4 Control panel

It consists a mounting near the welding head which as the following components

216

CITS : C G & M - Welder - Lesson 77 - 82