Page 227 - CITS - Welder - Trade Theory

P. 227

WELDER - CITS

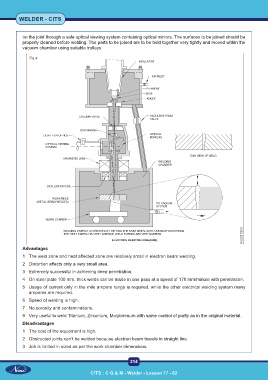

on the joint through a safe optical viewing system containing optical mirrors. The surfaces to be joined should be

properly cleaned before welding. The parts to be joined are to be held together very tightly and moved within the

vacuum chamber using suitable trolleys

Fig 4

Advantages

1 The weld zone and heat affected zone are relatively small in electron beam welding.

2 Distortion affects only a very small area.

3 Extremely successful in achieving deep penetration.

4 On steel plate 100 mm. thick welds can be made in one pass at a speed of 170 mm/minute with penetration.

5 Usage of current only in the mile ampere range is required, while the other electrical welding system many

amperes are required.

6 Speed of welding is high.

7 No porosity and contaminations.

8 Very useful to weld Titanium, Zirconium, Molybdenum with same control of purity as in the original material.

Disadvantages

1 The cost of the equipment is high.

2 Obstructed joints can’t be welded because electron beam travels in straight line.

3 Job is limited in sized as per the work chamber dimensions.

214

CITS : C G & M - Welder - Lesson 77 - 82