Page 225 - CITS - Welder - Trade Theory

P. 225

WELDER - CITS

Equipment and setup

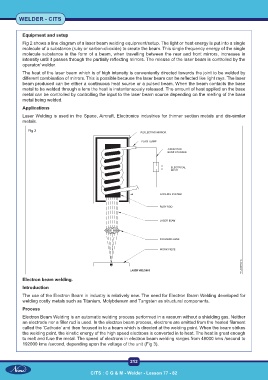

Fig 2 shows a line diagram of a laser beam welding equipment/setup. The light or heat energy is put into a single

molecule of a substance (ruby or carbon-di-oxide) to create the beam. This single frequency energy of the single

molecule substance in the form of a beam, when travelling between the rear and front mirrors, increases in

intensity until it passes through the partially reflecting mirrors. The release of the laser beam is controlled by the

operator/ welder.

The heat of the laser beam which is of high intensity is conveniently directed towards the joint to be welded by

different combination of mirrors. This is possible because the laser beam can be reflected like light rays. The laser

beam produced can be either a continuous heat source or a pulsed beam. When the beam contacts the base

metal to be welded through a lens the heat is instantaneously released. The amount of heat applied on the base

metal can be controlled by controlling the input to the laser beam source depending on the melting of the base

metal being welded.

Applications

Laser Welding is used in the Space, Aircraft, Electronics industries for thinner section metals and dis-similar

metals.

Fig 2

Electron beam welding.

Introduction

The use of the Electron Beam in industry is relatively new. The need for Electron Beam Welding developed for

welding costly metals such as Titanium, Molybdenum and Tungsten as structural components.

Process

Electron Beam Welding is an automatic welding process performed in a vacuum without a shielding gas. Neither

an electrode nor a filler rod is used. In the electron beam process, electrons are emitted from the heated filament

called the ‘Cathode’ and then focused in to a beam which is directed at the welding point. When the beam strikes

the welding point, the kinetic energy of the high speed electrons is converted in to heat. The heat is great enough

to melt and fuse the metal. The speed of electrons in electron beam welding ranges from 48000 kms /second to

192000 kms /second, depending upon the voltage of the unit (Fig 3).

212

CITS : C G & M - Welder - Lesson 77 - 82