Page 95 - CTS - Dress Making - TP - Volume - 1

P. 95

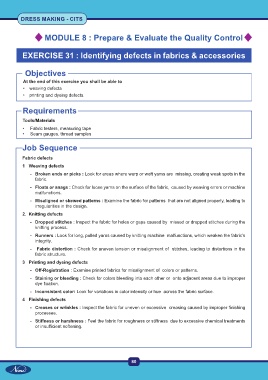

DRESS MAKING - CITS

MODULE 8 : Prepare & Evaluate the Quality Control

EXERCISE 31 : Identifying defects in fabrics & accessories

Objectives

At the end of this exercise you shall be able to

• weaving defects

• printing and dyeing defects.

Requirements

Tools/Materials

• Fabric testers, measuring tape

• Seam gauges, thread samples

Job Sequence

Fabric defects

1 Weaving defects

- Broken ends or picks : Look for areas where warp or weft yarns are missing, creating weak spots in the

fabric.

- Floats or snags : Check for loose yarns on the surface of the fabric, caused by weaving errors or machine

malfunctions.

- Misaligned or skewed patterns : Examine the fabric for patterns that are not aligned properly, leading to

irregularities in the design.

2. Knitting defects

- Dropped stitches : Inspect the fabric for holes or gaps caused by missed or dropped stitches during the

knitting process.

- Runners : Look for long, pulled yarns caused by knitting machine malfunctions, which weaken the fabric’s

integrity.

- Fabric distortion : Check for uneven tension or misalignment of stitches, leading to distortions in the

fabric structure.

3 Printing and dyeing defects

- Off-Registration : Examine printed fabrics for misalignment of colors or patterns.

- Staining or bleeding : Check for colors bleeding into each other or onto adjacent areas due to improper

dye fixation.

- Inconsistent color: Look for variations in color intensity or hue across the fabric surface.

4 Finishing defects

- Creases or wrinkles : Inspect the fabric for uneven or excessive creasing caused by improper finishing

processes.

- Stiffness or harshness : Feel the fabric for roughness or stiffness due to excessive chemical treatments

or insufficient softening.

80