Page 34 - Electrician - TT (Volume 1)

P. 34

ELECTRICIAN - CITS ELECTRICIAN - CITS

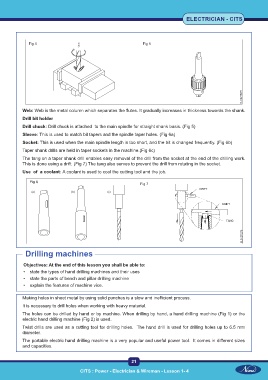

Fig 4 Fig 5

Web: Web is the metal column which separates the flutes. It gradually increases in thickness towards the shank.

Drill bit holder

Drill chuck: Drill chuck is attached to the main spindle for straight shank basis. (Fig 5)

Sleeve: This is used to match bit tapers and the spindle taper holes. (Fig 6a)

Socket: This is used when the main spindle length is too short, and the bit is changed frequently. (Fig 6b)

Taper shank drills are held in taper sockets in the machine.(Fig 6c)

The tang on a taper shank drill enables easy removal of the drill from the socket at the end of the drilling work.

This is done using a drift. (Fig 7) The tang also serves to prevent the drill from rotating in the socket.

Use of a coolant: A coolant is used to cool the cutting tool and the job.

Fig 6 Fig 7

Drilling machines

Objectives: At the end of this lesson you shall be able to:

• state the types of hand drilling machines and their uses

• state the parts of bench and pillar drilling machine

• explain the features of machine vice.

Making holes in sheet metal by using solid punches is a slow and inefficient process.

It is necessary to drill holes when working with heavy material.

The holes can be drilled by hand or by machine. When drilling by hand, a hand drilling machine (Fig 1) or the

electric hand drilling machine (Fig 2) is used.

Twist drills are used as a cutting tool for drilling holes. The hand drill is used for drilling holes up to 6.5 mm

diameter.

The portable electric hand drilling machine is a very popular and useful power tool. It comes in different sizes

and capacities.

20 21

CITS : Power - Electrician & Wireman - Lesson 1- 4