Page 129 - Electrician - TT (Volume 2)

P. 129

ELECTRICIAN - CITS

Types and construction of alternators

Objectives: At the end of this lesson you shall be able to:

• explain the construction, and the various types of alternators

Classification according to the number of phases: Another way of classifying the alternators is based on

production of single or 3-phase by the alternator. Accordingly the types are 1) single-phase alternators 2) three-

phase alternators.

Single-phase alternators: A single-phase alternator is one that provides only one voltage. The armature coils

are connected in `series additive’. In other words, the sum of the emf induced in each coil produces the total

output voltage. Single phase alternators are usually constructed in small sizes only. They are used as a temporary

standby power for construction sites and for permanent installation in remote locations.

Three-phase alternators: This alternator provides two different voltages, namely, phase and line voltages. It

has 3 windings placed at 120° to each other, mostly connected in a star having three main terminals U,V,W and

neutral `N’.

These alternators are driven by prime movers such as diesel engines, steam turbines, water wheels etc. depending

upon the source available.

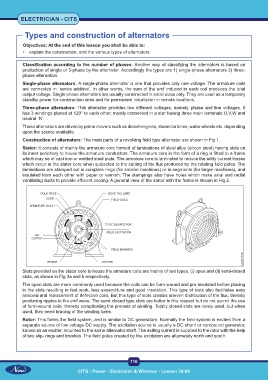

Construction of alternators: The main parts of a revolving field type alternator are shown in Fig 1.

Stator: It consists of mainly the armature core formed of laminations of steel alloy (silicon steel) having slots on

its inner periphery to house the armature conductors. The armature core in the form of a ring is fitted to a frame

which may be of cast iron or welded steel plate. The armature core is laminated to reduce the eddy current losses

which occur in the stator core when subjected to the cutting of the flux produced by the rotating field poles. The

laminations are stamped out in complete rings (for smaller machines) or in segments (for larger machines), and

insulated from each other with paper or varnish. The stampings also have holes which make axial and radial

ventilating ducts to provide efficient cooling. A general view of the stator with the frame is shown in Fig 2.

Slots provided on the stator core to house the armature coils are mainly of two types, (i) open and (ii) semi-closed

slots, as shown in Fig 3a and b respectively.

The open slots are more commonly used because the coils can be form-wound and pre-insulated before placing

in the slots resulting in fast work, less expenditure and good insulation. This type of slots also facilitates easy

removal and replacement of defective coils. But this type of slots creates uneven distribution of the flux, thereby

producing ripples in the emf wave. The semi-closed type slots are better in this respect but do not permit the use

of form-wound coils, thereby complicating the process of winding. Totally closed slots are rarely used, but when

used, they need bracing of the winding turns.

Rotor: This forms the field system, and is similar to DC generators. Normally the field system is excited from a

separate source of low voltage DC supply. The excitation source is usually a DC shunt or compound generator,

known as an exciter, mounted to the same alternator shaft. The exiting current is supplied to the rotor with the help

of two slip- rings and brushes. The field poles created by the excitation are alternately north and south.

116

CITS : Power - Electrician & Wireman - Lesson 76-85