Page 14 - Electrician - TT (Volume 2)

P. 14

ELECTRICIAN - CITS

MODULE 11 : Electronics

LESSON 60-69: Resistors, Colour code, types and

characteristics

Objectives

At the end of this lesson you shall be able to

• explain construction, types, colour coding and application of resistors in circuits.

Resistors: These are the most common passive component used in electronic circuits. A resistor is manufactured

with a specific value of ohms (resistance). The purpose of using a resistor in circuit is either to limit the current

to a specific value or to provide a desired voltage drop (IR). The power rating of resistors may be from 0.1 W. to

hundreds of Watts.

There are four types of resistors

1 Wire-wound resistors

2 Carbon composition resistors

3 Metal film resistors

4 Carbon film resistors

1 Wire-wound resistors

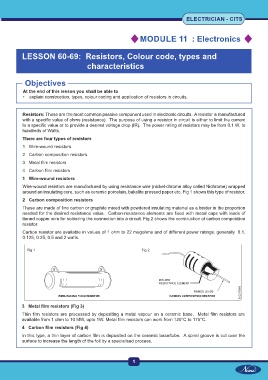

Wire-wound resistors are manufactured by using resistance wire (nickel-chrome alloy called Nichrome) wrapped

around an insulating core, such as ceramic porcelain, bakelite pressed paper etc. Fig 1 shows this type of resistor.

2 Carbon composition resistors

These are made of fine carbon or graphite mixed with powdered insulating material as a binder in the proportion

needed for the desired resistance value. Carbon-resistance elements are fixed with metal caps with leads of

tinned copper wire for soldering the connection into a circuit. Fig 2 shows the construction of carbon composition

resistor.

Carbon resistor are available in values of 1 ohm to 22 megohms and of different power ratings, generally 0.1,

0.125, 0.25, 0.5 and 2 watts.

Fig 1 Fig 2

3 Metal film resistors (Fig 3)

Thin film resistors are processed by depositing a metal vapour on a ceramic base. Metal film resistors are

available from 1 ohm to 10 MW, upto 1W. Metal film resistors can work from 120°C to 175°C.

4 Carbon film resistors (Fig 4)

In this type, a thin layer of carbon film is deposited on the ceramic base/tube. A spiral groove is cut over the

surface to increase the length of the foil by a specialised process.

1