Page 162 - Electrician - TT (Volume 2)

P. 162

ELECTRICIAN - CITS

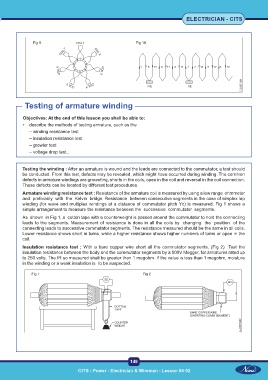

Fig 9 Fig 10

Testing of armature winding

Objectives: At the end of this lesson you shall be able to:

• describe the methods of testing armature, such as the

– winding resistance test

– insulation resistance test

– growler test

– voltage drop test..

Testing the winding : After an armature is wound and the leads are connected to the commutator, a test should

be conducted. From this test, defects may be revealed, which might have occurred during winding. The common

defects in armature windings are grounding, shorts in the coils, open in the coil and reversal in the coil connection.

These defects can be located by different test procedures.

Armature winding resistance test : Resistance of the armature coil is measured by using a low range ohmmeter

and preferably with the Kelvin bridge. Resistance between consecutive segments in the case of simplex lap

winding (for wave and multiplex windings at a distance of commutator pitch Yc) is measured. Fig 1 shows a

simple arrangement to measure the resistance between the successive commutator segments.

As shown in Fig 1, a cotton tape with a counterweight is passed around the commutator to hold the connecting

leads to the segments. Measurement of resistance is done in all the coils by changing the position of the

connecting leads to successive commutator segments. The resistance measured should be the same in all coils.

Lower resistance shows short in turns, while a higher resistance shows higher numbers of turns or open in the

coil.

Insulation resistance test : With a bare copper wire short all the commutator segments. (Fig 2) Test the

insulation resistance between the body and the commutator segments by a 500V Megger, for armatures rated up

to 250 volts. The IR so measured shall be greater than 1 megohm. If the value is less than 1 megohm, moisture

in the winding or a weak insulation is to be suspected.

Fig 1 Fig 2

148 149

CITS : Power - Electrician & Wireman - Lesson 86-92