Page 169 - Electrician - TT (Volume 2)

P. 169

ELECTRICIAN - CITS

Wire sizes and turns

Primary - 3187 turns of size 0.16 mm or 37 SWG

Secondary - 88 turns of size 1.00 mm or 19 SWG

Stampings: Considering the thickness of each stamping as 0.35 mm, for the total thickness of 21 mm we may

require 60 stampings. Considering the space between stampings and the stacking we may require 55 stampings

only. Hence EI 60/21 type 55 numbers of stampings having 0.35 mm thickness are to be procured.

Testing of transformer after rewinding: After rewinding the core assembly, the transformer is to be inspected

for proper tightness of the core and coil as well as proper termination of the end leads.

Insulation resistance test : Insulation resistance is measured between windings and core with a 500 volts

Megger. The reading so obtained shall be infinity and in no case below one megohm.

Transformation ratio test: Keeping the transformer secondary open, the primary shall be connected to the rated

AC voltage. With the help of suitable voltmeters both the primary and secondary voltage shall be measured.

Load test : The transformer shall be connected with a suitable load, so that the full load secondary current flows

through the secondary of the transformer winding. The raise in the winding temperature shall be observed by a

suitable industrial thermometer, on the load.

The transformer temperature will raise initially and after some time the temperature will come to a standstill. This

raise in temperature shall be noted and it shall be within the limit of class of insulation of the transformer designed.

Short circuit test : Where it is not possible to load the transformer directly, the secondary winding of the

transformer shall be short circuited and the low voltage on the primary shall be adjusted through a dimmerstat

so that full load secondary current flows through the secondary winding of the transformer. The transformer so

switched on shall be tested for raise in temperature to ascertain the class of insulation.

Generally oil-cooled transformers are of class-A where-as air-cooled transformers may be class

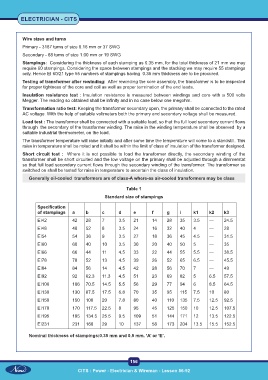

Table 1

Standard size of stampings

Specification

of stampings a b c d e f g i k1 k2 k3

EI42 42 28 7 3.5 21 14 28 35 3.5 — 24.5

EI48 48 52 8 3.5 24 16 32 40 4 — 28

EI54 54 36 9 3.5 27 18 36 45 4.5 — 31.5

EI60 60 40 10 3.5 30 20 40 50 5 — 35

EI66 66 44 11 4.5 33 22 44 55 5.5 — 38.5

EI78 78 52 13 4.5 39 26 52 65 6.5 — 45.5

EI84 84 56 14 4.5 42 28 56 70 7 — 49

EI92 92 62.3 11.3 4.5 51 23 69 82 5 6.5 57.5

EI106 106 70.5 14.5 5.5 56 29 77 94 6 8.5 64.5

EI130 130 87.5 17.5 6.8 70 35 95 115 7.5 10 80

EI150 150 100 20 7.8 80 40 110 135 7.5 12.5 92.5

EI170 170 117.5 22.5 8 95 45 125 150 10 12.5 107.5

EI195 195 134.5 25.5 9.5 109 51 144 171 12 13.5 122.5

EI231 231 166 29 10 137 58 173 204 13.5 15.5 152.5

Nominal thickness of stampings:0.35 mm and 0.5 mm. ‘A’ or ‘E’.

156 PB

CITS : Power - Electrician & Wireman - Lesson 86-92