Page 237 - Electrician - TT (Volume 2)

P. 237

ELECTRICIAN - CITS

Cutting and drilling

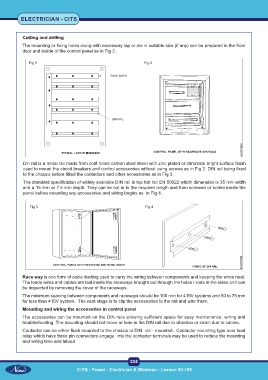

The mounting or fixing holes along with necessary tap or die in suitable size (if any) can be prepared in the front

door and inside of the control panel as in Fig 2.

Fig 1 Fig 2

Din rail is a metal rail made from cold rolled carbon steel sheet with zinc plated or chromate bright surface finish

used to mount the circuit breakers and control accessories without using screws as in Fig 2. DIN rail being fixed

to the chassis before fitted the contactors and other accessories as in Fig 3.

The standard specification of widely available DIN rail is top hat rail EN 50022 which dimension is 35 mm width

and a 15 mm or 7.5 mm depth. They can be cut in to the required length and then screwed or bolted inside the

panel before mounting any accessories and wiring begins as in Fig 4.

Fig 3 Fig 4

Race way is one form of cable ducting used to carry the wiring between components and keeping the wires neat.

The leads wires and cables are laid inside the raceways brought out through the holes / slots in the sides and can

be inspected by removing the cover of the raceways.

The minimum spacing between components and raceways should be 100 mm for 415V systems and 50 to 75 mm

for less than 415V system. The next stage is to clip the accessories to the rail and wire them.

Mounting and wiring the accessories in control panel

The accessories can be mounted on the DIN rails allowing sufficient space for easy maintenance, wiring and

troubleshooting. The mounting should not move or lean in the DIN rail due to vibration or strain due to cables.

Contactor can be either flush mounted to the chassis or DIN rail - mounted . Contactor mounting type over load

relay which have three pin connectors engage into the contactor terminals may be used to reduce the mounting

and wiring time and labour.

224

CITS : Power - Electrician & Wireman - Lesson 93-100 CITS : Power - Electrician & Wireman - Lesson 93-100