Page 234 - Electrician - TT (Volume 2)

P. 234

ELECTRICIAN - CITS

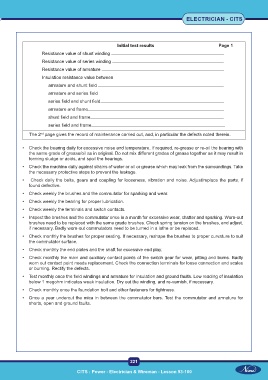

Initial test results Page 1

Resistance value of shunt winding

Resistance value of series winding

Resistance value of armature

Insulation resistance value between

armature and shunt field

armature and series field

series field and shunt field

armature and frame

shunt field and frame

series field and frame

The 2 page gives the record of maintenance carried out, and, in particular the defects noted therein.

nd

• Check the bearing daily for excessive noise and temperature. If required, re-grease or re-oil the bearing with

the same grade of grease/oil as in original. Do not mix different grades of grease together as it may result in

forming sludge or acids, and spoil the bearings.

• Check the machine daily against strains of water or oil or grease which may leak from the surroundings. Take

the necessary protective steps to prevent the leakage.

• Check daily the belts, gears and coupling for looseness, vibration and noise. Adjust/replace the parts, if

found defective.

• Check weekly the brushes and the commutator for sparking and wear.

• Check weekly the bearing for proper lubrication.

• Check weekly the terminals and switch contacts.

• Inspect the brushes and the commutator once in a month for excessive wear, chatter and sparking. Worn-out

brushes need to be replaced with the same grade brushes. Check spring tension on the brushes, and adjust,

if necessary. Badly worn-out commutators need to be turned in a lathe or be replaced.

• Check monthly the brushes for proper seating. If necessary, reshape the brushes to proper curvature to suit

the commutator surface.

• Check monthly the end plates and the shaft for excessive end play.

• Check monthly the main and auxiliary contact points of the switch gear for wear, pitting and burns. Badly

worn out contact point needs replacement. Check the connection terminals for loose connection and scales

or burning. Rectify the defects.

• Test monthly once the field windings and armature for insulation and ground faults. Low reading of insulation

below 1 megohm indicates weak insulation. Dry out the winding, and re-varnish, if necessary.

• Check monthly once the foundation bolt and other fasteners for tightness.

• Once a year undercut the mica in between the commutator bars. Test the commutator and armature for

shorts, open and ground faults.

221

CITS : Power - Electrician & Wireman - Lesson 93-100 CITS : Power - Electrician & Wireman - Lesson 93-100