Page 238 - Electrician - TT (Volume 2)

P. 238

ELECTRICIAN - CITS

To mount the contactor on rail first place the back top groove on the top of rail and turn it downwards against the

lower rail which will cause the spring of the contactor to retract and snap into place behind the rail. There is a slot

in the spring clip of the contactor so that the clip can be retracted using small screw driver or connector to remove

the contactor if required. To avoid fouling the underneath of the accessories use screws with low profile heads.

The contactor arrangements and terminals are usually labeled which conforms to BS 5583. For example 1 and 2

for NC contacts, 3 and 4 for NO contacts, odd numbers like 1, 3 and 5 for incoming terminals and even numbers

like 2, 4 and 6 for outgoing terminals of the main contacts of contactors and OLR.

The conductor should be trimmed off to that the conductor does not insert more than the half way through the

connectors. Single strand wire should be folded back to give additional thickness. The over tightening of screw

have to be avoided otherwise this can crush the strand and give a weak connection.

All the internal wiring should be terminated in the top and external wiring in the bottom of the connectors to avoid

the crossover of both wirings. Flexible conduit and cables have to be installed in such a way that the liquid or

water if any can drain away from the fitting and grommets.

An earth terminal usually green or green yellow to be clamped to the rail and ensure the cabinet and door are

earthed properly.

An insulated separator can be used to isolate the high voltage connections from others. End stops are used to

clamps the connectors together and close the open terminals on one end, sometimes the earth terminal will do

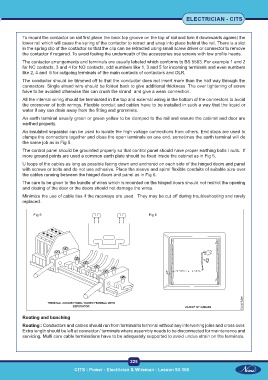

the same job as in Fig 5.

The control panel should be grounded properly so that control panel should have proper earthing bolts / nuts. If

more ground points are used a common earth plate should be fixed inside the cabinet as in Fig 5.

U loops of the cables as long as possible facing down and anchored on each side of the hinged doors and panel

with screws or bolts and do not use adhesive. Place the sleeve and spiral flexible conduits of suitable size over

the cables running between the hinged doors and panel as in Fig 6.

The care to be given to the bundle of wires which is mounted on the hinged doors should not restrict the opening

and closing of the door or the doors should not damage the wires.

Minimize the use of cable ties if the raceways are used. They may be cut off during troubleshooting and rarely

replaced.

Fig 5 Fig 6

Routing and bunching

Routing : Conductors and cables should run from terminal to terminal without any intervening joins and cross over.

Extra length should be left at connector / terminals where assembly needs to be disconnected for maintenance and

servicing. Multi core cable terminations have to be adequately supported to avoid undue strain on the terminals.

225

CITS : Power - Electrician & Wireman - Lesson 93-100 CITS : Power - Electrician & Wireman - Lesson 93-100