Page 231 - Electrician - TT (Volume 2)

P. 231

ELECTRICIAN - CITS

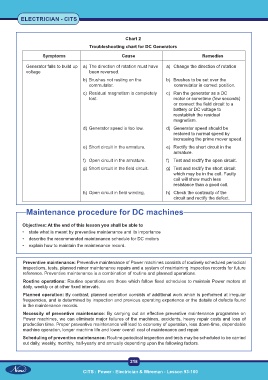

Chart 2

Troubleshooting chart for DC Generators

Symptoms Cause Remedies

Generator fails to build up a) The direction of rotation must have a) Change the direction of rotation

voltage been reversed.

b) Brushes not resting on the b) Brushes to be set over the

commutator. commutator in correct position.

c) Residual magnetism is completely c) Run the generator as a DC

lost. motor or sometime (few seconds)

or connect the field circuit to a

battery or DC voltage to

reestablish the residual

magnetism.

d) Generator speed is too low. d) Generator speed should be

restored to normal speed by

increasing the prime mover speed.

e) Short circuit in the armature. e) Rectify the short circuit in the

armature.

f) Open circuit in the armature. f) Test and rectify the open circuit.

g) Short circuit in the field circuit. g) Test and rectify the short circuit

which may be in the coil. Faulty

coil will show much less

resistance than a good coil.

h) Open circuit in field winding. h) Check the continuity of the

circuit and rectify the defect.

Maintenance procedure for DC machines

Objectives: At the end of this lesson you shall be able to

• state what is meant by preventive maintenance and its importance

• describe the recommended maintenance schedule for DC motors

• explain how to maintain the maintenance record.

Preventive maintenance: Preventive maintenance of Power machines consists of routinely scheduled periodical

inspections, tests, planned minor maintenance repairs and a system of maintaining inspection records for future

reference. Preventive maintenance is a combination of routine and planned operations.

Routine operations: Routine operations are those which follow fixed schedules to maintain Power motors at

daily, weekly or at other fixed intervals.

Planned operation: By contrast, planned operation consists of additional work which is performed at irregular

frequencies, and is determined by inspection and previous operating experience or the details of defects found

in the maintenance records.

Necessity of preventive maintenance: By carrying out an effective preventive maintenance programme on

Power machines, we can eliminate major failures of the machines, accidents, heavy repair costs and loss of

production time. Proper preventive maintenance will lead to economy of operation, less down-time, dependable

machine operation, longer machine life and lower overall cost of maintenance and repair.

Scheduling of preventive maintenance: Routine periodical inspection and tests may be scheduled to be carried

out daily, weekly, monthly, half-yearly and annually depending upon the following factors.

218

CITS : Power - Electrician & Wireman - Lesson 93-100