Page 226 - Electrician - TT (Volume 2)

P. 226

ELECTRICIAN - CITS

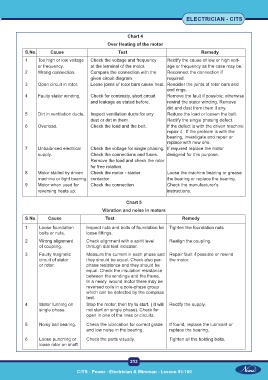

Chart 4

Over Heating of the motor

S.No. Cause Test Remedy

1 Too high or low voltage Check the voltage and frequency Rectify the cause of low or high volt-

or frequency. at the terminal of the motor. age or frequency as the case may be.

2 Wrong connection. Compare the connection with the Reconnect the connection if

given circuit diagram. required.

3 Open circuit in rotor. Loose joints of rotor bars cause heat. Resolder the joints of rotor bars and

end rings.

4 Faulty stator winding. Check for continuity, short circuit Remove the fault if possible; otherwise

and leakage as stated before. rewind the stator winding. Remove

dirt and dust from them if any.

5 Dirt in ventilation ducts. Inspect ventilation ducts for any Reduce the load or loosen the belt.

dust or dirt in them. Rectify the single phasing defect.

6 Overload. Check the load and the belt. If the defect is with the driven machine

repair it. If the problem is with the

bearing, investigate and repair or

replace with new one.

7 Unbalanced electrical Check the voltage for single phasing. If required replace the motor

supply. Check the connections and fuses. designed for this purpose.

Remove the load and check the rotor

for free rotation.

8 Motor stalled by driven Check the motor - starter Loose the machine bearing or grease

machine or tight bearing. contactor the bearing or replace the bearing.

9 Motor when used for Check the connection Check the manufacturer’s

reversing heats up. instructions.

Chart 5

Vibration and noise in motors

S.No. Cause Test Remedy

1 Loose foundation Inspect nuts and bolts of foundation for Tighten the foundation nuts.

bolts or nuts. loose fittings.

2 Wrong alignment Check alignment with a spirit level Realign the coupling.

of coupling. through dial test indicator.

3 Faulty magnetic Measure the current in each phase and Repair fault if possible or rewind

circuit of stator they should be equal. Check also per- the motor.

or rotor. phase resistance and they should be

equal. Check the insulation resistance

between the windings and the frame.

In a newly wound motor there may be

reversed coils in a pole-phase group

which can be detected by the compass

test.

4 Motor running on Stop the motor, then try to start. ( It will Rectify the supply.

single phase. not start on single phase). Check for

open in one of the lines or circuits.

5 Noisy ball bearing. Check the lubrication for correct grade If found, replace the lubricant or

and low noise in the bearing. replace the bearing.

6 Loose punching or Check the parts visually. Tighten all the holding bolts.

loose rotor on shaft.

213

CITS : Power - Electrician & Wireman - Lesson 93-100 CITS : Power - Electrician & Wireman - Lesson 93-100