Page 227 - Electrician - TT (Volume 2)

P. 227

ELECTRICIAN - CITS

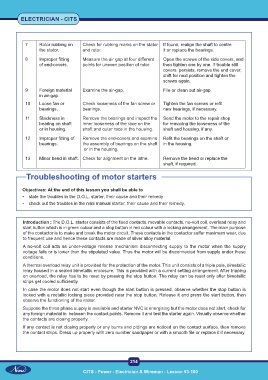

7 Rotor rubbing on Check for rubbing marks on the stator If found, realign the shaft to centre

the stator. and rotor. it or replace the bearings.

8 Improper fitting Measure the air gap at four different Open the screws of the side covers, and

of end-covers. points for uneven position of rotor then tighten one by one. If trouble still

covers. persists, remove the end cover,

shift for next position and tighten the

screws again.

9 Foreign material Examine the air-gap. File or clean out air-gap.

in air-gap.

10 Loose fan or Check looseness of the fan screw or Tighten the fan screws or refit

bearings. bearings. new bearings, if necessary.

11 Slackness in Remove the bearings and inspect the Send the motor to the repair shop

bearing on shaft inner looseness of the race on the for removing the looseness of the

or in housing. shaft and outer race in the housing. shaft and housing, if any.

12 Improper fitting of Remove the end-covers and examine Refit the bearings on the shaft or

bearings. the assembly of bearings on the shaft in the housing.

or in the housing.

13 Minor bend in shaft. Check for alignment on the lathe. Remove the bend or replace the

shaft, if required.

Troubleshooting of motor starters

Objectives: At the end of this lesson you shall be able to

• state the troubles in the D.O.L. starter, their cause and their remedy

• check out the troubles in the mini manual starter, their cause and their remedy.

Introduction : The D.O.L. starter consists of the fixed contacts, movable contacts, no-volt coil, overload relay and

start button which is in green colour and a stop button in red colour with a locking arrangement. The main purpose

of the contactor is to make and break the motor circuit. These contacts in the contactor suffer maximum wear, due

to frequent use and hence these contacts are made of silver alloy material.

A no-volt coil acts as under-voltage release mechanism disconnecting supply to the motor when the supply

voltage fails or is lower than the stipulated value. Thus the motor will be disconnected from supply under these

conditions.

A thermal overload relay unit is provided for the protection of the motor. This unit consists of a triple pole, bimetallic

relay housed in a sealed bimetallic enclosure. This is provided with a current setting arrangement. After tripping

on overload, the relay has to be reset by pressing the stop button. The relay can be reset only after bimetallic

strips get cooled sufficiently.

In case the motor does not start even though the start button is pressed, observe whether the stop button is

locked with a metallic locking piece provided near the stop button. Release it and press the start button, then

observe the functioning of the motor.

Suppose the three phase supply is available and starter NVC is energising but the motor does not start, check for

any foreign material in between the contact points. Remove it and test the starter again. Visually observe whether

the contacts are closing properly.

If any contact is not closing properly or any burns and pittings are noticed on the contact surface, then remove

the contact strips. Dress up properly with zero number sandpaper or with a smooth file or replace it if necessary.

214

CITS : Power - Electrician & Wireman - Lesson 93-100