Page 286 - Electrician - TT (Volume 2)

P. 286

ELECTRICIAN - CITS

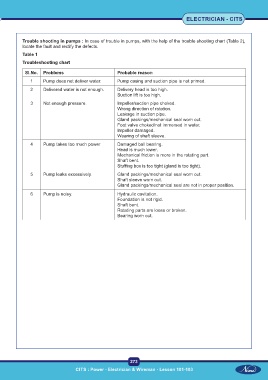

Trouble shooting in pumps : In case of trouble in pumps, with the help of the trouble shooting chart (Table 2),

locate the fault and rectify the defects.

Table 1

Troubleshooting chart

Sl.No. Problems Probable reason

1 Pump does not deliver water. Pump casing and suction pipe is not primed.

2 Delivered water is not enough. Delivery head is too high.

Suction lift is too high.

3 Not enough pressure. Impeller/suction pipe choked.

Wrong direction of rotation.

Leakage in suction pipe.

Gland packings/mechanical seal worn out.

Foot valve choked/not immersed in water.

Impeller damaged.

Wearing of shaft sleeve.

4 Pump takes too much power Damaged ball bearing.

Head is much lower.

Mechanical friction is more in the rotating part.

Shaft bent.

Stuffing box is too tight (gland is too tight).

5 Pump leaks excessively. Gland packings/mechanical seal worn out.

Shaft sleeve worn out.

Gland packings/mechanical seal are not in proper position.

6 Pump is noisy. Hydraulic cavitation.

Foundation is not rigid.

Shaft bent.

Rotating parts are loose or broken.

Bearing worn out.

273

CITS : Power - Electrician & Wireman - Lesson 101-103