Page 282 - Electrician - TT (Volume 2)

P. 282

ELECTRICIAN - CITS

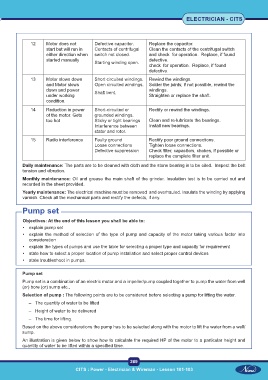

12 Motor does not Defective capacitor. Replace the capacitor.

start but will run in Contacts of centrifugal Clean the contacts of the centrifugal switch

either direction when switch not closed. and check for operation. Replace, if found

started manually defective.

Starting winding open.

check for operation. Replace, if found

defective.

13 Motor slows down Short circuited windings. Rewind the windings.

and Motor slows Open circuited windings. Solder the joints; if not possible, rewind the

down and power Shaft bent. windings.

under working Straighten or replace the shaft.

condition.

14 Reduction in power Short-circuited or Rectify or rewind the windings.

of the motor. Gets grounded windings.

too hot Sticky or tight bearings Clean and re-lubricate the bearings.

Interference between Install new bearings.

stator and rotor.

15 Radio interference Faulty ground Rectify poor ground connections.

Loose connections Tighten loose connections.

Defective suppression Check filter, capacitors, chokes, if possible or

replace the complete filter unit.

Daily maintenance: The parts are to be cleaned with cloth and the stone bearing is to be oiled. Inspect the belt

tension and vibration.

Monthly maintenance: Oil and grease the main shaft of the grinder. Insulation test is to be carried out and

recorded in the sheet provided.

Yearly maintenance: The electrical machine must be removed and overhauled. Insulate the winding by applying

varnish. Check all the mechanical parts and rectify the defects, if any.

Pump set

Objectives: At the end of this lesson you shall be able to:

• explain pump set

• explain the method of selection of the type of pump and capacity of the motor taking various factor into

consideration

• explain the types of pumps and use the table for selecting a proper type and capacity for requirement

• state how to select a proper location of pump installation and select proper control devices

• state troubleshoot in pumps.

Pump set

Pump set is a combination of an electric motor and a impeller/pump coupled together to pump the water from well

(or) bore (or) sump etc.,

Selection of pump : The following points are to be considered before selecting a pump for lifting the water.

– The quantity of water to be lifted

– Height of water to be delivered

– The time for lifting.

Based on the above considerations the pump has to be selected along with the motor to lift the water from a well/

sump.

An illustration is given below to show how to calculate the required HP of the motor to a particular height and

quantity of water to be lifted within a specified time.

269

CITS : Power - Electrician & Wireman - Lesson 101-103