Page 277 - Electrician - TT (Volume 2)

P. 277

ELECTRICIAN - CITS

The time rating of running the mixer varies from 1 minute to 60 minutes depending upon the type. A tapped field

coil enables speed selection through a rotary or push button switch.The food mixer normally runs at 3 speeds.

Maintenance and servicing of a food mixer: The manufacturer’s service manual, if available, read it a

number of times and follow the instruction. First listen to the complaint from the customer and make a note of it.

Visually check the mixer right from the plug to the speed selector switch connections and enter the details in the

maintenance card.

Test the mixer with and without the power cord for the continuity and insulation resistance. The insulation resistance

value for the individual part should not be less than 1 Megohm. the power cord should be 3-core and the plug and

socket should be of 3-pin/socket type with effective earth.

But double insulated (PVC body) mixers may have two core cable and 2-pin plug type. A damaged plug or power

cord should be replaced. Check the brush tension and make it normal. Check the brush length; if found short by

2/3rd of its original length, replace it with the same specification brush or a brush obtained from the manufacturer

of the mixer.

Check the switch for its proper function. Better to replace a faulty one with a new one having the same specification.

Before opening the motor assembly, check the couplings for their proper form. Check the ply of the shaft and

vertical movement to get an idea of the condition of the bearings.

Tight bearing may be due to misalignment, bend in the shaft, dried grease or lubricant, dirt, damaged commutator

or due to damaged bearing.

Check the winding for burnt smell or discoloured look. Ascertain through the tests whether the winding is shorted,

open or has lost its insulation resistance value. If required rewind or get the rewinding done from outside agencies.

While tightening the screws on the motor housing, spin the armature with your fingers at intervals during the

assembling process to ensure that it is not getting bound.

Fix the jar/container on the drive coupling.

Connect the supply cord as per the circuit diagram.

Test the mixer for continuity and insulation resistance. Minimum acceptable insulation resistance value is 1

Megohm.

Connect the supply, and test for its working.

Repairs

Some of the common troubles encountered in the repair of mixers are given in the Table 1 which also gives the

possible causes and their remedies.

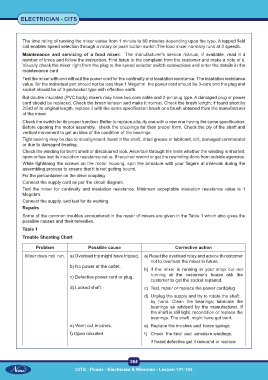

Table 1

Trouble Shooting Chart

Problem Possible cause Corrective action

Mixer does not run. a) Overload trip might have tripped. a) Reset the overload relay and advice th customer

not to overload the mixer in future.

b) No power at the outlet.

b) If the mixer is running in your shop but not

c) Defective power cord or plug. running at the customer’s house ask the

customer to get the socket repaired.

d) Locked shaft. c) Test, repair or replace the power cord/plug.

d) Unplug the supply and try to rotate the shaft

by hand. Clean the bearings; lubricate the

bearings as advised by the manufacturer. If

the shaft is still tight, recondition or replace the

bearings. The shaft might have got bent.

e) Worn out brushes. e) Replace the brushes and loose springs

f) Open circuited. f) Check the field and armature windings.

If found defective get it rewound or replace

264

CITS : Power - Electrician & Wireman - Lesson 101-103