Page 280 - Electrician - TT (Volume 2)

P. 280

ELECTRICIAN - CITS

Stone: The grinder stone consists of two parts of stones. One male and one female. The male part grinds the

grains during rotation against conical cavity in the base (female stone). This female part is actually attached to

the stainless steel container which rotates when the motor is energised. Both the stones are manufactured with

hard granite which is usually whitish black in colour.

Pulley: The drum speed is lower than the motor speed, normally 500 to 600 r.p.m. The motor speed is normally

1450 r.p.m. and the speed of the drum is reduced by using a larger diameter pulley than the driven pulley, usually

in the ratio of 1:3. The transmission of force between the driver pulley and the driven pulley is through a V belt of

type No A 36 or A 39 (Fig 4).

Fig 4

Frame and stand: The grinding stones, motor pulleys are all housed in a rectangular frame with sunmica or

stainless steel covering or plastic moulding for decoration as well as safety. A separate vertical stand is provided

on one side of the grinder for holding the male grinding stone. If the MS frame is used, it is usually to be

chromium plated.

Wet grinder- maintenance and servicing: In wet grinders, the trouble may be classified into two types. Electrical

faults and Mechanical faults. Some mechanical faults create electrical faults too.

Some common problems and their rectifications are given in the Table 1.

Safety measures

• Make sure power is turned off before working on electrical equipment.

• Plug to be removed from the socket.

Maintenance practices: An electrical machine or appliance to be maintained according to the programme

already made. Certain maintenance practices to be observed are,

– Daily maintenance

– Monthly maintenance

– Yearly maintenance

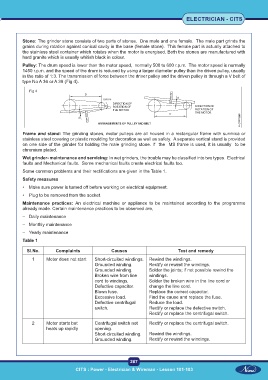

Table 1

Sl.No. Complaints Causes Test and remedy

1 Motor does not start Short-circuited windings. Rewind the windings.

Grounded winding. Rectify or rewind the windings.

Grounded winding. Solder the joints; if not possible rewind the

Broken wire from line windings.

cord to windings. Solder the broken wire in the line cord or

Defective capacitor. change the line cord.

Blown fuse. Replace the correct capacitor.

Excessive load. Find the cause and replace the fuse.

Defective centrifugal Reduce the load.

switch. Rectify or replace the defective switch.

Rectify or replace the centrifugal switch.

2 Motor starts but Centrifugal switch not Rectify or replace the centrifugal switch.

heats up rapidly opening.

Short-circuited winding. Rewind the windings.

Grounded winding. Rectify or rewind the windings.

267

CITS : Power - Electrician & Wireman - Lesson 101-103