Page 345 - Electrician - TT (Volume 2)

P. 345

ELECTRICIAN - CITS

Maintenance is also required at fixed and moving contacts of OCB. Alloy metals are used to make the tips of

contacts part in conductors. But in usage these contacts are partially melted or damaged or repaired frequently

otherwise quenching time will increase rapidly.

The tension of loading springs and manual operating levers are to be checked and rectified if any mechanical part

is found defective. The coils, electromagnets and other electrical parts are to be checked for its effectiveness. A

comprehensive service flow chart is attached for detailed repair and maintenance.

Maintenance & repair of SF6 circuit breaker

It is a advanced version and compact to use mainly for indoor substation. Since the SF6 gas is poisonous proper

protective gadgets are to be used while handling SF6 circuit breaker.

The loading, tripping mechanism almost same as that of VCB and air blast ACB. The maintenance and repair

mentioned may have to follow in this case also.

The main maintenance requirement in SF6 circuit breaker are handling gas or charging gas. No recondition is

possible the SF6 total replacement is required in case of any gas failure. More cycle of operation will cause the

reduction of gas strength and reducing gas pressure also will be the reason of SF6 circuit breaker failure.

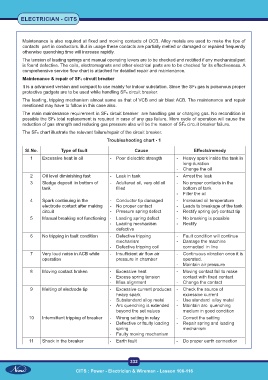

The SF6 chart illustrate the relevant failure/repair of the circuit breaker.

Troubleshooting chart - 1

Sl.No. Type of fault Cause Effects/remedy

1 Excessive heat in oil - Poor dielectric strength - Heavy spark inside the tank in

long duration

- Change the oil

2 Oil level diminishing fast - Leak in tank - Arrest the leak

3 Sledge deposit in bottom of - Adultered oil, very old oil - No proper contacts in the

tank filled bottom of tank

- Filter the oil

4 Spark continuing in the - Conductor tip damaged - Increased oil temperature

electrode contact after making - No proper contact - Leads to breakage of the tank

circuit - Pressure spring defect - Rectify spring (or) contact tip

5 Manual breaking not functioning - Loading spring defect - No breaking is possible

- Loading mechanism - Rectify

defective

6 No tripping in fault condition - Defective tripping - Fault condition will continue

mechanism - Damage the machine

- Defective tripping coil connected in line

7 Very loud noise in ACB while - Insufficient air flow air - Continuous vibration once it is

operation pressure in chamber operated.

- Maintain air pressure

8 Moving contact broken - Excessive heat - Moving contact fail to make

- Excess spring tension contact with fixed contact

- Miss alignment - Change the contact

9 Melting of electrode tip - Excessive current produces - Check the source of

heavy spark excessive current

- Substandard alloy metal - Use standard alloy metal

- Arc quenching is extended - Maintain arc quenching

beyond the set values medium in good condition

10 Intermittent tripping of breaker - Wrong setting in relay - Correct the setting

- Deflective or faulty loading - Repair spring and loading

spring mechanism

- Faulty moving mechanism

11 Shock in the breaker - Earth fault - Do proper earth connection

332

CITS : Power - Electrician & Wireman - Lesson 106-116