Page 163 - CITS - Fitter Trade Pactical - Volume - 2

P. 163

FITTER - CITS

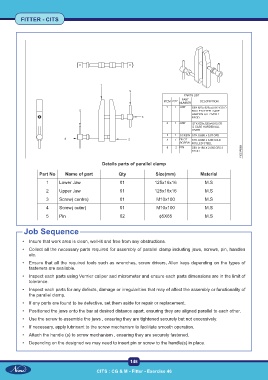

Details parts of parallel clamp

Part No Name of part Qty Size(mm) Material

1 Lower Jaw 01 125x16x16 M.S

2 Upper Jaw 01 125x16x16 M.S

3 Screw( centre) 01 M10x100 M.S

4 Screw( outer) 01 M10x100 M.S

5 Pin 02 ɸ5X65 M.S

Job Sequence

• Insure that work area is clean, well-lit and free from any obstructions.

• Collect all the necessary parts required for assembly of parallel clamp including jaws, screws, pin, handles

etc.

• Ensure that all the required tools such as wrenches, screw drivers, Allen keys depending on the types of

fasteners are available.

• Inspect each parts using Vernier caliper and micrometer and ensure each parts dimensions are in the limit of

tolerance.

• Inspect each parts for any defects, damage or irregularities that may ef affect the assembly or functionality of

the parallel clamp.

• If any parts are found to be defective, set them aside for repair or replacement.

• Positioned the jaws onto the bar at desired distance apart, ensuring they are aligned parallel to each other.

• Use the screw to assemble the jaws , ensuring they are tightened securely but not excessively.

• If necessary, apply lubricant to the screw mechanism to facilitate smooth operation.

• Attach the handle (s) to screw mechanism , ensuring they are securely fastened.

• Depending on the designed we may need to insert pin or screw to the handle(s) in place.

148

CITS : CG & M - Fitter - Exercise 46